|

|||

|

|

|||

|

Page Title:

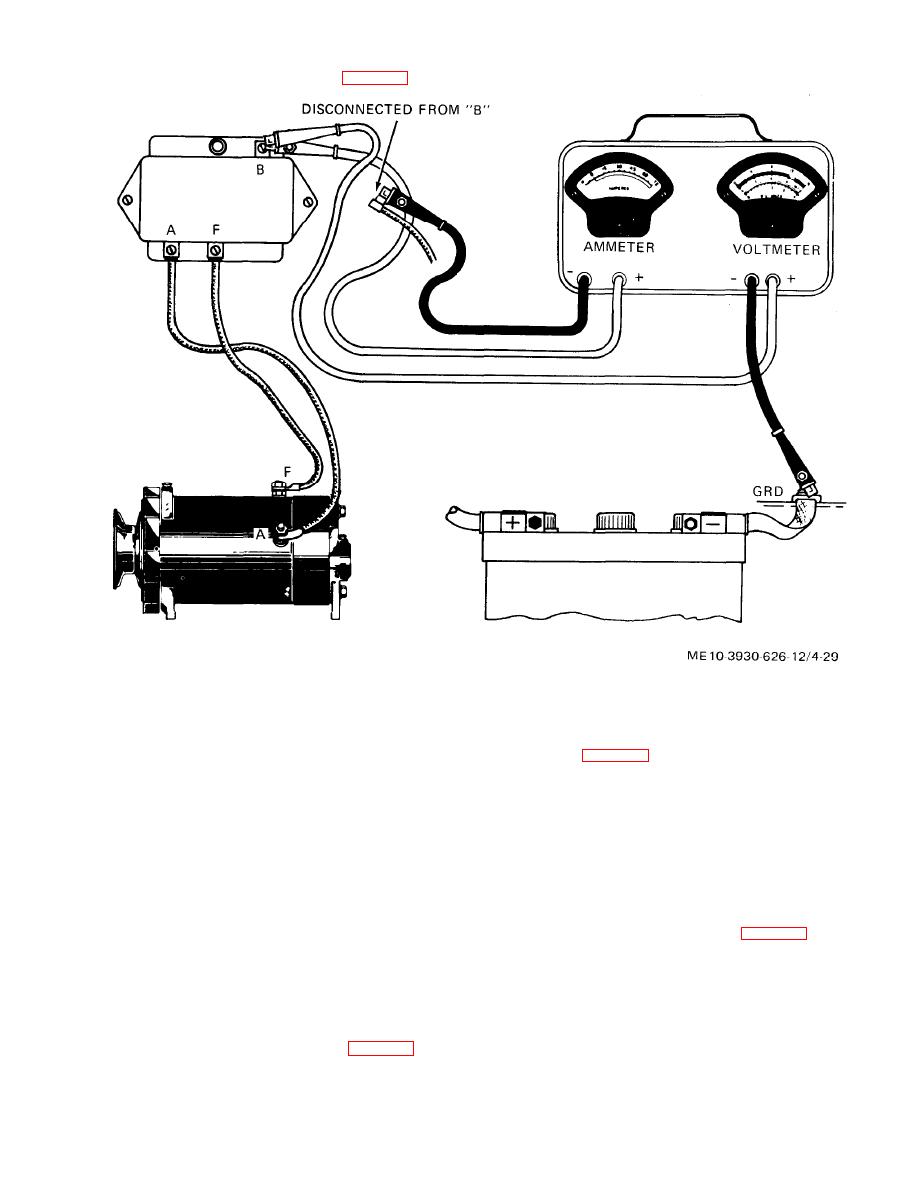

Figure 4-29. Voltage regulator test setup. |

|

||

| ||||||||||

|

|

(b) Electrical test.

requires two checks and adjustments as follows:

2. Run engine at 1500 rpm.

3. Turn on headlights and if necessary,

(a) Air gap. W i t h b a t t e r y d i s c o n n e c t e d ,

check air gap (fig. 4-27). Insert gage on contact

apply load across battery until test ammeter reads

point side of air gap next to armature stop rivet. If

approximately 7 amperes.

adjustment is needed, loosen bracket adjusting

4. Cycle regulator by reducing speed

screw and raise or lower contact point bracket until

until cutout relay points open, then slowly increase

speed again to 1500 rpm.

a gap of 0.048 to 0.052 inch is obtained. Tighten

b r a c k e t adjusting screw securely after making

adjustment. When armature is held down so that

voltage regulator unit. Reading should be 14.2 to

stop rivet rests on magnet core, point gap should be

14.8 volts.

a minimum of 0.012 inch.

(b) Electrical test.

dirty or pitted contact points.

6. W h e n a d j u s t i n g v o l t a g e r e g u l a t o r ,

2. Run engine at 2000 rpm.

repeat steps 4 and 5 above after each adjustment

3. Apply a variable load across battery

and before taking final reading. Final test reading

until ammeter reading is maximum.

m u s t be made with cover in place at normal

4. Maximum ammeter reading indicates

operating temperature.

setting of current regulator unit. Reading should be

7. If voltage regulator is not within limits,

30 amperes.

bend lower armature spring anchor (fig. 4-27) to

obtain proper voltage.

burned or pitted contact points.

(3) Current regulator. The current regulator

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |