|

|||

|

|

|||

|

Page Title:

LOSS OF MIDDLE FRAME LOAD HOLDING. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

The LHS hydraulic system operates at oil pressures up to 3675 psi (25,339 kPa). Never disconnect any

S

hydraulic line or fitting without first dropping pressure to zero. Failure to comply may result in serious

injury or death to personnel.

Fuel and oil are slippery and can cause falls. To avoid injury, wipe up spilled fuel or oil with rags.

S

All personnel must stand clear during lifting operations. A swinging or shifting load may cause injury or

S

death to personnel.

VISUAL INSPECTION

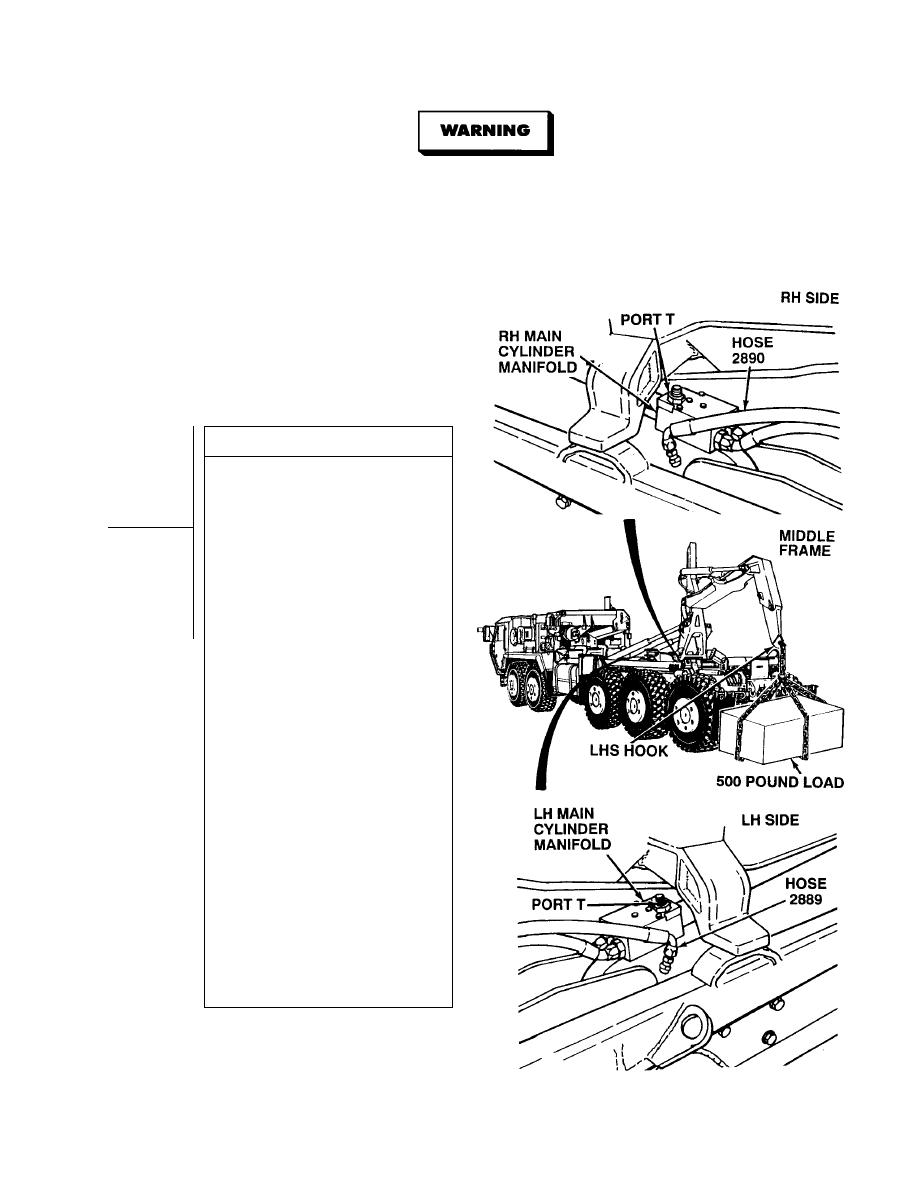

(1) Position LHS hook to rear of truck

(TM 9-2320-364-10).

(2) Attach 500 lb (227 kg) minimum

load to hook.

(3) Lower middle frame approximately

half of its travel.

(4) Set hydraulic selector switch to OFF

position.

(5) Turn OFF ENGINE switch.

(6) Disconnect hose 2889 from LH

main cylinder manifold, port T. Plug

disconnected hose.

(7) Disconnect hose 2890 from RH

main cylinder manifold, port T.

Plug disconnected hose.

(a) If no fluid leaks from LH or RH

main cylinder manifolds where

hoses were removed, main

cylinder manifold relief valves

are OK. Perform Steps (8)

through (13) below and go to

Step 3 of this Fault.

(b) If fluid leaks from LH or RH main

cylinder manifold where hose is

removed, relief valve is faulty.

Perform Steps (8) through (13)

below and repair main cylinder

manifold (Para 17-16).

(8) Remove plug from hose 2890 and

connect hose to LH main cylinder

manifold, port T.

(9) Remove plug from hose 2889 and

connect hose to RH main cylinder

manifold, port T.

(10) Remove 500 lb (227 kg) load from

LHS hook.

(11) Put LHS in transit position.

(12) Set hydraulic selector switch

to OFF position.

(13) Turn OFF engine.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |