|

|||

|

|

|||

|

Page Title:

MIDDLE FRAME DOES NOT LOAD. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

The LHS hydraulic system operates at oil

S

pressures up to 3675 psi (25,339 kPa).

Never disconnect any hydraulic line or

fitting without first dropping pressure

to zero. Failure to comply may result in

serious injury or death to personnel.

Fuel and oil are slippery and can cause

S

falls. To avoid injury, wipe up spilled

fuel or oil with rags.

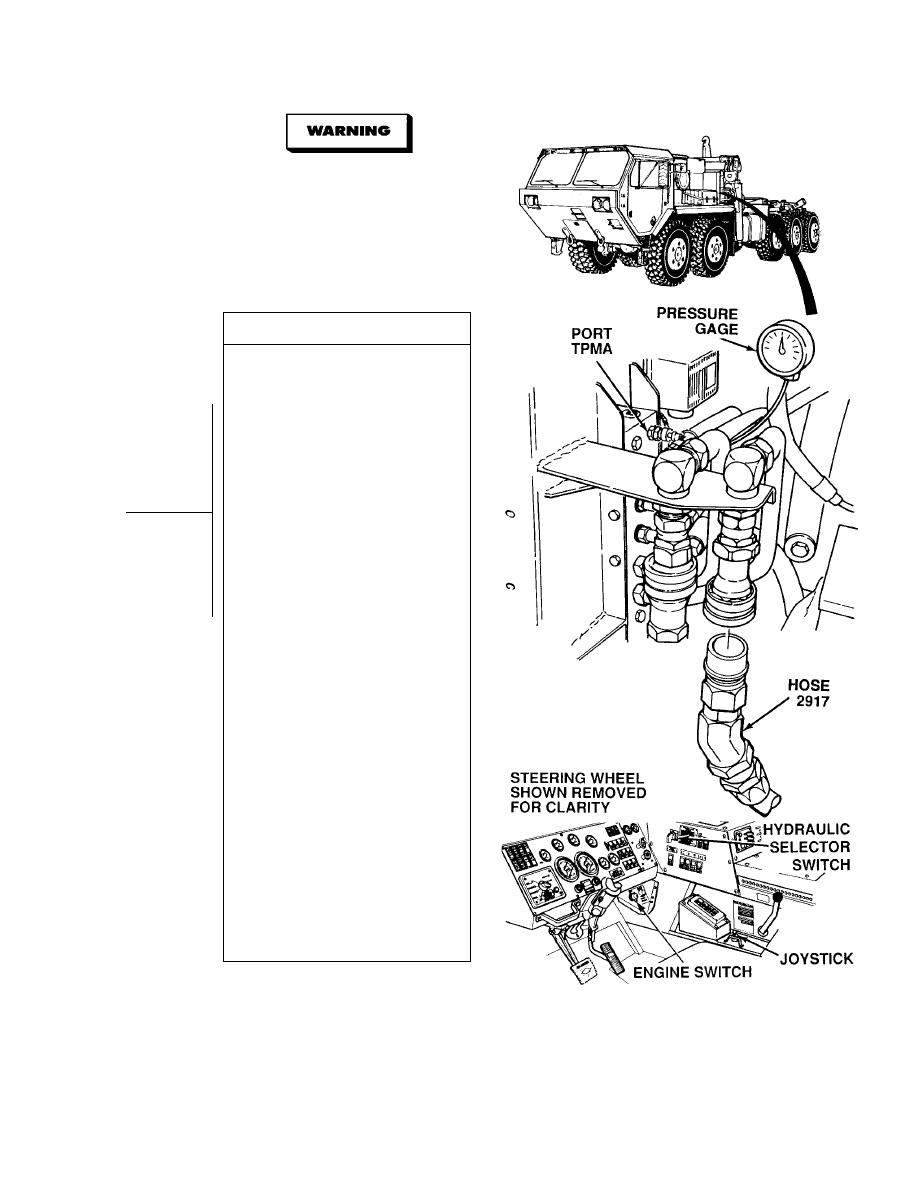

PRESSURE TEST

(1) Disconnect hose 2917 male quick

disconnect from LHS control box

female quick disconnect.

(2) Remove plug from main manifold,

port TPMA.

(3) Remove preformed packing and

backup ring from plug. Discard

preformed packing and backup ring.

(4) Connect pressure gage to main

manifold, port TPMA.

(5) Connect quick disconnect

hose 2917.

(6) Start engine (TM 9-2320-364-10).

(7) Set hydraulic selector switch to

MAN MF.

(8) Raise main frame approximately 24

in. (61 cm).

(9) With the aid of an assistant, observe

pressure gage while holding

joystick in LOAD position.

(a) If more than 1300 psi (8964 kPa)

are present, perform Steps (10)

and (16) below and replace RH

(inboard) main cylinder

manifold load control valve

(Para 17-6).

(b) If 1300 psi (8964 kPa) or less

are present, load control valve

is OK.

(10) Set hydraulic selector switch to OFF

position.

(11) Turn OFF ENGINE switch.

(12) Disconnect hose 2917 male quick

disconnect from LHS control box

female quick disconnect.

(13) Remove pressure gage from main

manifold.

(14) Lubricate preformed packing and

backup ring with hydraulic oil.

(15) Install preformed packing and

backup ring on plug and install

plug in main manifold, port TPMA.

Tighten to 96 lb-in (11 N.m).

(16) Connect quick disconnect

hose 2917.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |