|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-364-20-1

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads

and gloves. Hot engine components will burn and cause personnel injury.

Use jumperwire only between terminals

indicated. Failure to comply may result in

damage to DDEC components or wiring.

DDEC ECM connector terminals are easily

damaged. Use care when connecting and

disconnecting connectors.

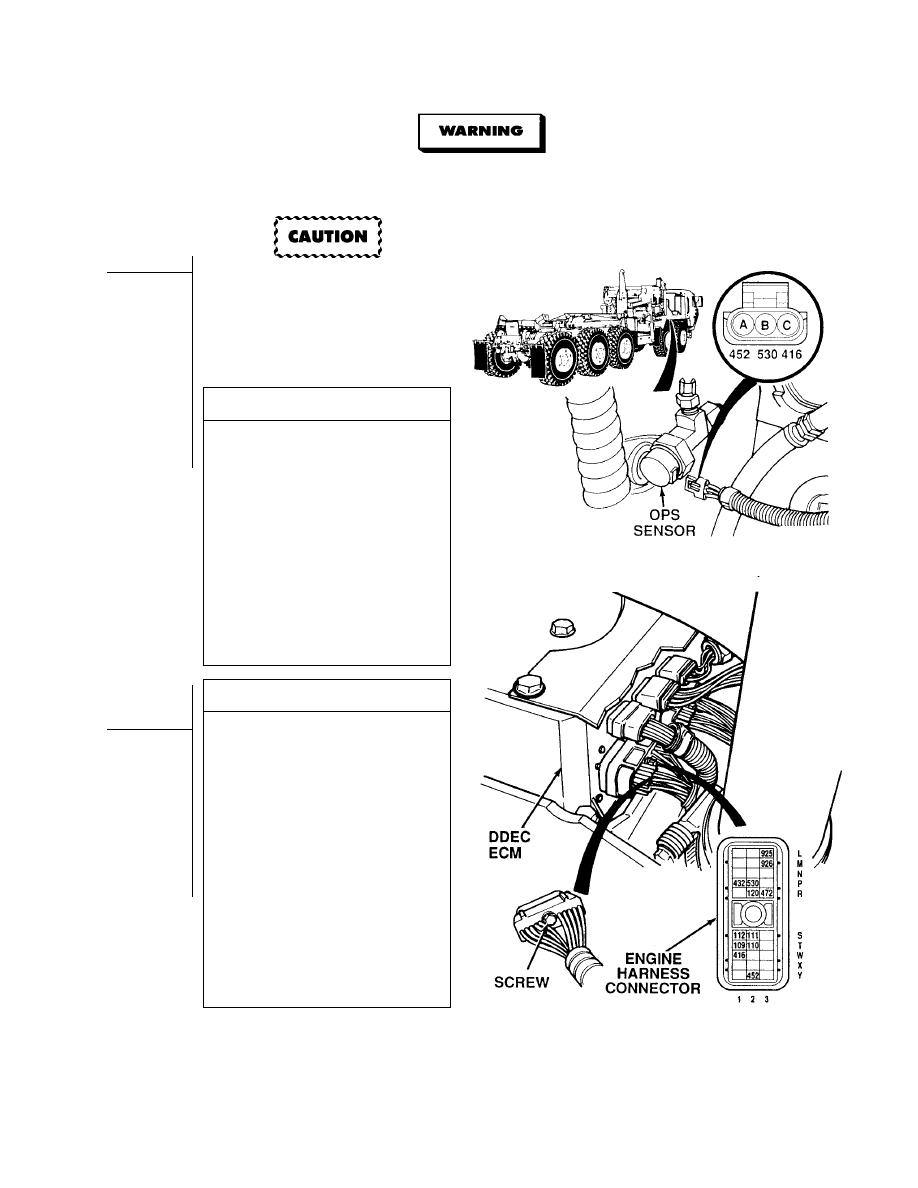

RESISTANCE TEST

(1) Loosen screw and disconnect engine

harness connector at DDEC ECM.

(2) Place jumperwire between terminals

A and B at OPS harness connector.

(3) Set multimeter select switch to ohms.

(4) Read resistance between wires 452

and 530 at engine harness connector,

terminals P2 and Y2.

(a) If there are more than 5 ohms

present, perform Step (5) below

and repair wires 452 and/or

530 (see schematic Fig 2-2) or

notify DS Maintenance.

(b) If there are 5 ohms or less

present, wires 452 and 530

are OK.

(5) Remove jumperwire.

RESISTANCE TEST

(1) Read resistance between wires 452

and 530 at OPS harness connector,

terminals A and B.

(a) If there are less than 10,000 ohms

present, repair wires 452 and/or

530 (see schematic Fig 2-2) or

notify DS Maintenance.

(b) If there are more than 10,000

ohms present, go to Step (2)

below.

(2) Read resistance between wires 530

and 452 at OPS harness connector,

terminal B and A and a known good

ground.

(a) If there are less than 10,000 ohms

present, repair wire 530 or 452

(see schematic Fig 2-2) or notify

DS Maintenance.

(b) If there are more than 10,000

ohms present, wires 530 and 452

are OK.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |