|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-364-20-1

Allow engine to cool before performing

troubleshooting maintenance. If necessary

use insulated pads and gloves. Hot engine

components will burn and cause injury to

personnel.

DDEC ECM connector terminals are easily

damaged. Use care when connecting and

disconnecting connectors.

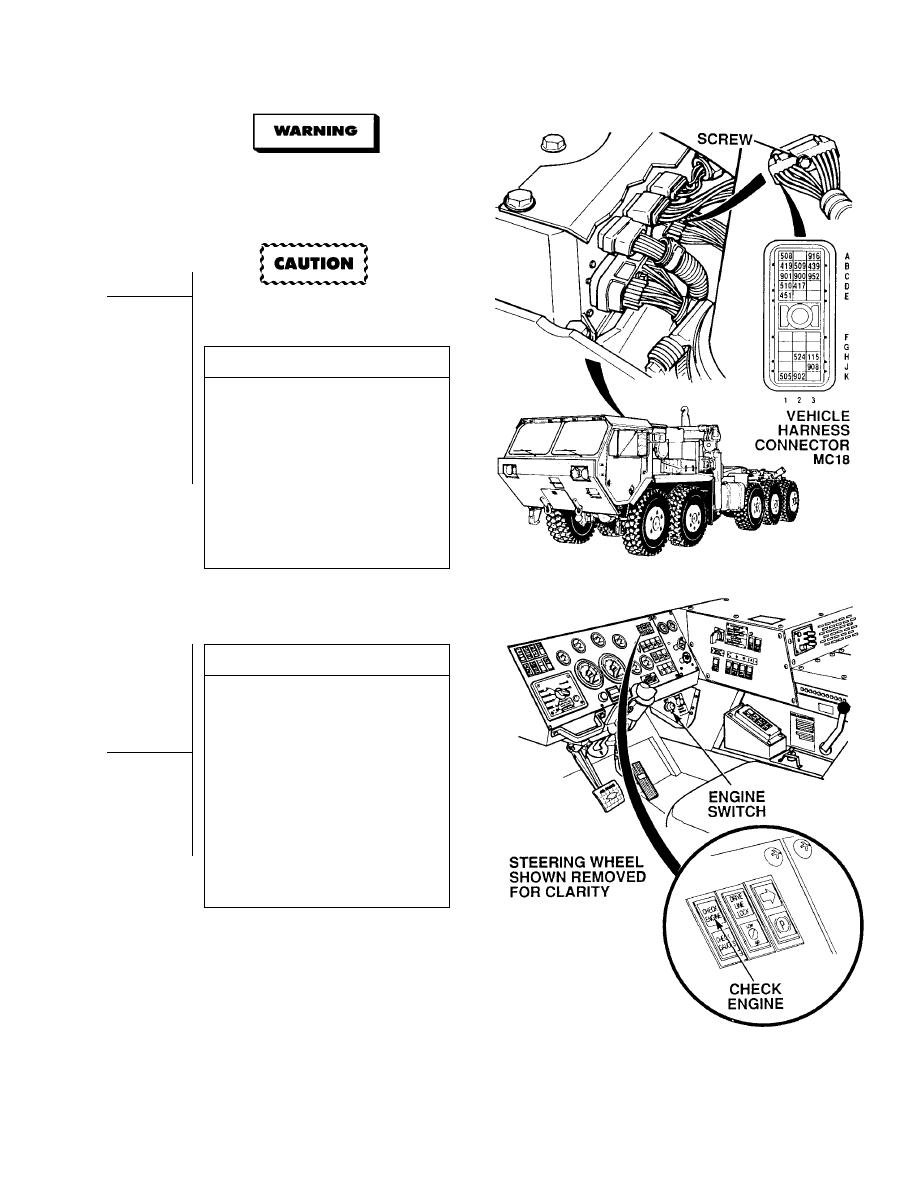

VISUAL INSPECTION

(1) Loosen screw and disconnect vehicle

harness connector MC18 from

DDEC ECM.

(2) Turn ON ENGINE switch

(TM 9-2320-364-10) and

observe CEL.

(a) If CEL stays on, turn OFF

ENGINE switch, and repair

wire 419 (see schematic Fig 2-1)

or notify DS Maintenance.

(b) If CEL goes off after five seconds,

wire 419 is OK.

(3) Turn OFF ENGINE switch.

VISUAL INSPECTION

(1) Check terminals at vehicle harness

connector MC18 (DDEC ECM and

harness side) for damage; bent,

corroded and unseated pins or

terminals.

(a) If harness connector MC18 is

damaged, repair connector

(Para 7-101).

(b) If harness connector MC18 is OK,

replace DDEC ECM (Para 7-56).

(c) If DDEC ECM connector MC18 is

damaged, replace DDEC ECM

(Para 7-56).

(2) Connect vehicle harness connector to

DDEC ECM and tighten screw.

(3) Close top engine cover.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |