|

|||

|

|

|||

|

Page Title:

Table 2-1. Unit Level Preventive Maintenance Checks and Services (PMCS) (CONT). |

|

||

| ||||||||||

|

|

TM 9-2320-364-20-1

2-9. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

TABLES (CONT).

Table 2-1. Unit Level Preventive Maintenance Checks and Services (PMCS) (CONT).

Interval

Item to Be

Procedure

Not Mission

Item

Inspected

Capable If:

No.

23

Semi-

Axles No.1

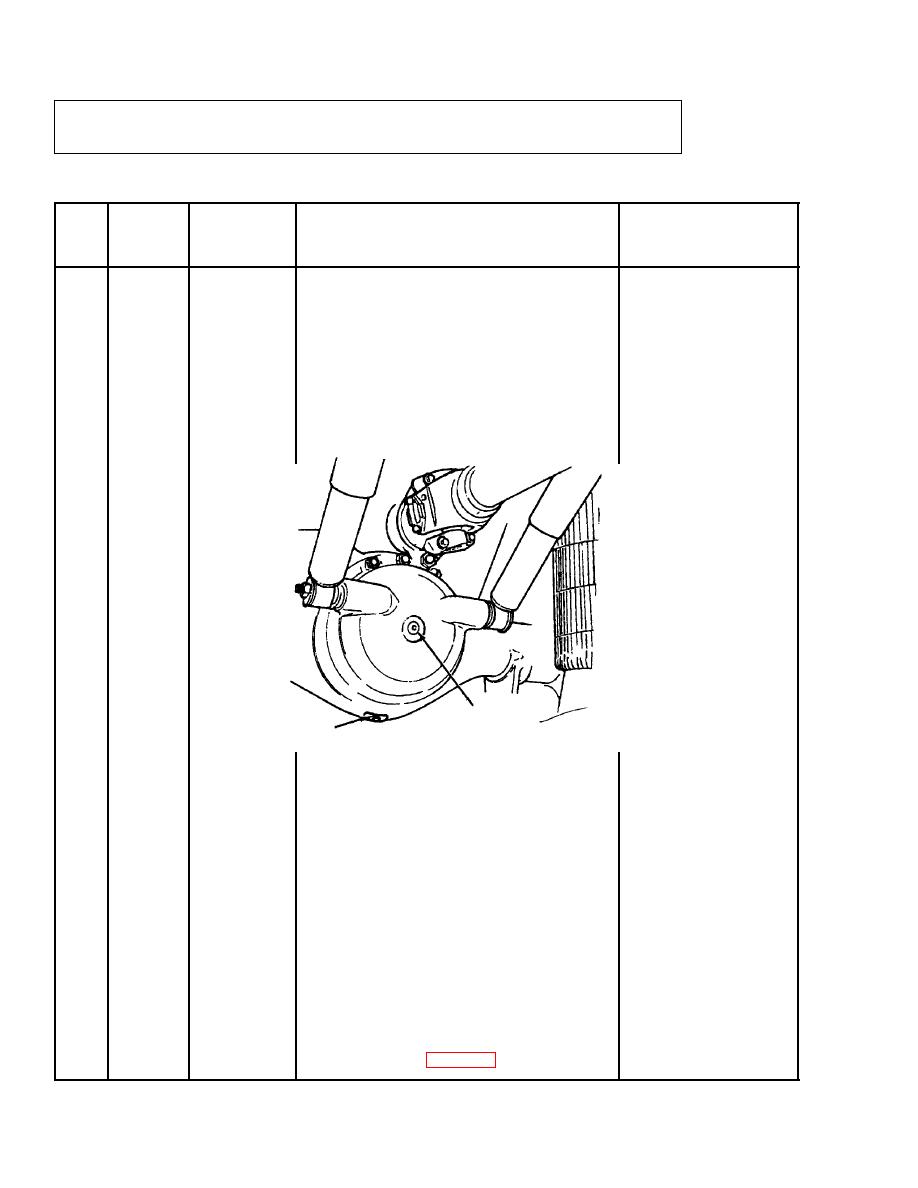

Check shaft seals for cuts, nicks, gouges and

Leaks or damage are

Annual

and No. 2

leaks. Check input and output yoke nuts for

found. Yoke nuts are

Shaft Seals

proper staking. Both staked points on nuts

loose, missing or not

and Yoke

should be in slots of pinion shafts.

staked.

Nuts

24

Semi-

Axles No. 1

Check constant velocity joints for wear, play

Joints are worn,

Annual

and No. 2

and damage.

damaged or have play.

Constant

Velocity

Joints

CHECK

AND

DRAIN PLUG

FILL PLUG

NOTE

Some oil will transfer from the wheel end to

the axle housing and a slight overfill

condition at the axle housing may be

noticed during checking of the axles. This

is considered normal and should not be a

reason for concern.

All axles are drained/filled the same way.

After draining, fill through the axle bowl to

a level even with the check and fill hole.

Allow the oil level to stabilize and recheck.

Add lubricant as needed.

25

Semi-

Differential

Check fluid level in the axle No. 3 differential

Any Class III leaks are

Annual

and Output

every 3,000 miles (4,828 km) or semiannually,

found.

Shaft

whichever comes first. Fill with GO as

(Axle No. 3)

required. Refer to Table 2-3.

2-26

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |