|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

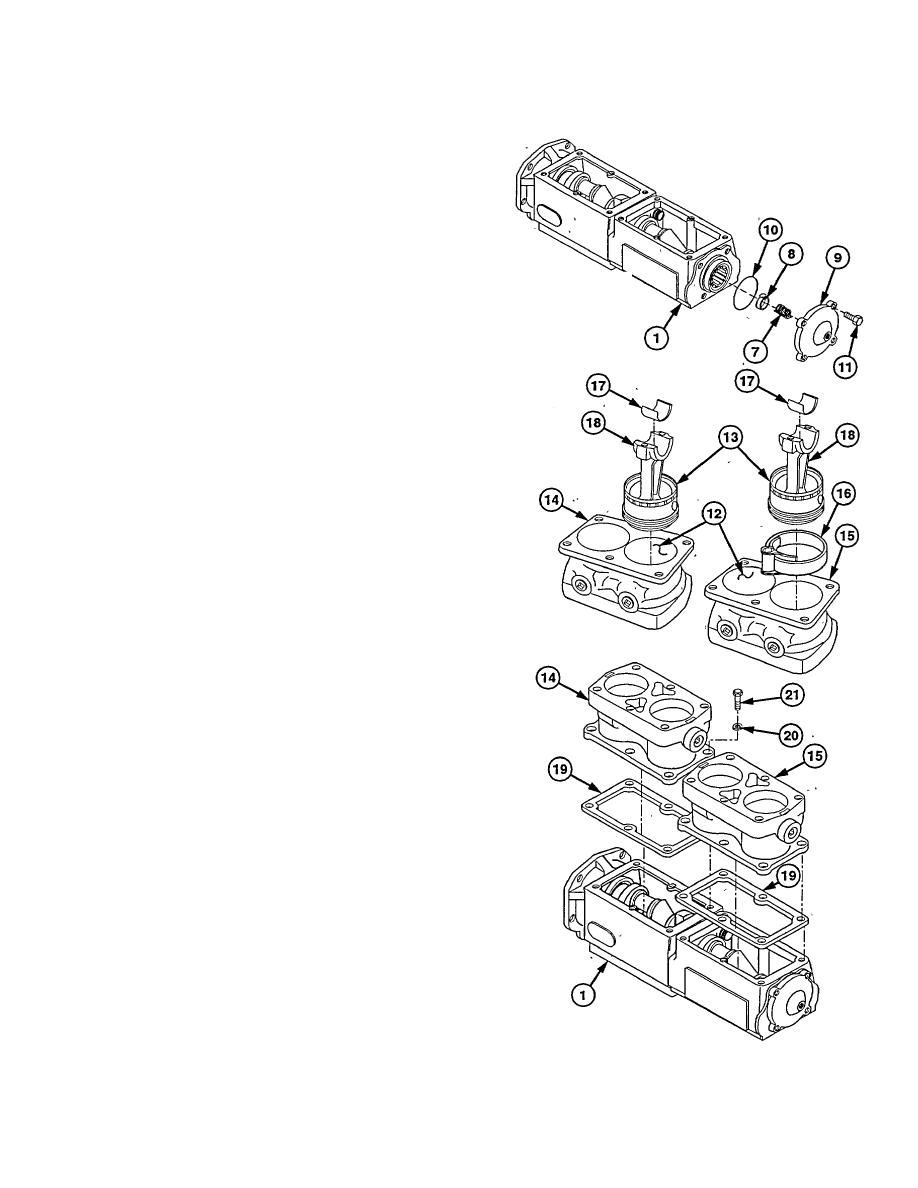

TM 9-2320-360-34-2

(5) Install spring (7) and oil flow regulator (8)

in bearing end cover (9).

(6) Install new preformed packing (10) in

bearing end cover (9).

NOTE

When properly installed, tab on oil

flow regulator should be up.

(7) Install bearing end cover (9) on crankcase

assembly (1) with four screws (11).

(8) Coat cylinder walls (12) and piston and

rod assemblies (13) with lubricating oil.

(9) Install four piston and rod assemblies (13)

in two cylinder blocks (14 and 15) using

piston ring compressor (16).

NOTE

Locating tabs on bearing halves must

Insert

in

locating

notches

in

connecting rods.

(10) Install two bearing

halves

(17)

on

connecting rods (18).

(11) Coat two bearing

halves

(17)

with

lubricating oil.

NOTE

Cylinder block should be installed on

crankcase as marked during removal.

(12) Install new gasket (19) and cylinder block

(14) on crankcase assembly (1).

NOTE

Two center screws should be

tightened to 96 lb-in. (11 Nm).

Four outer screws then should be

tightened to 96 lb-in. (11 Nm).

Two center screws then should be

tightened to 27-33 Ib-ft (37-45

Nm).

Four outer screw s then should be

tightened to 27-33 Ib-ft (37-45

Nm).

(13) Install six new lockwashers (20) and

screws (21) on cylinder block (14).

Torque to 27-33 lb-ft (37-45 Nm).

(14) Repeat steps (10) thru (13) for cylinder

block (15).

26-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |