|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

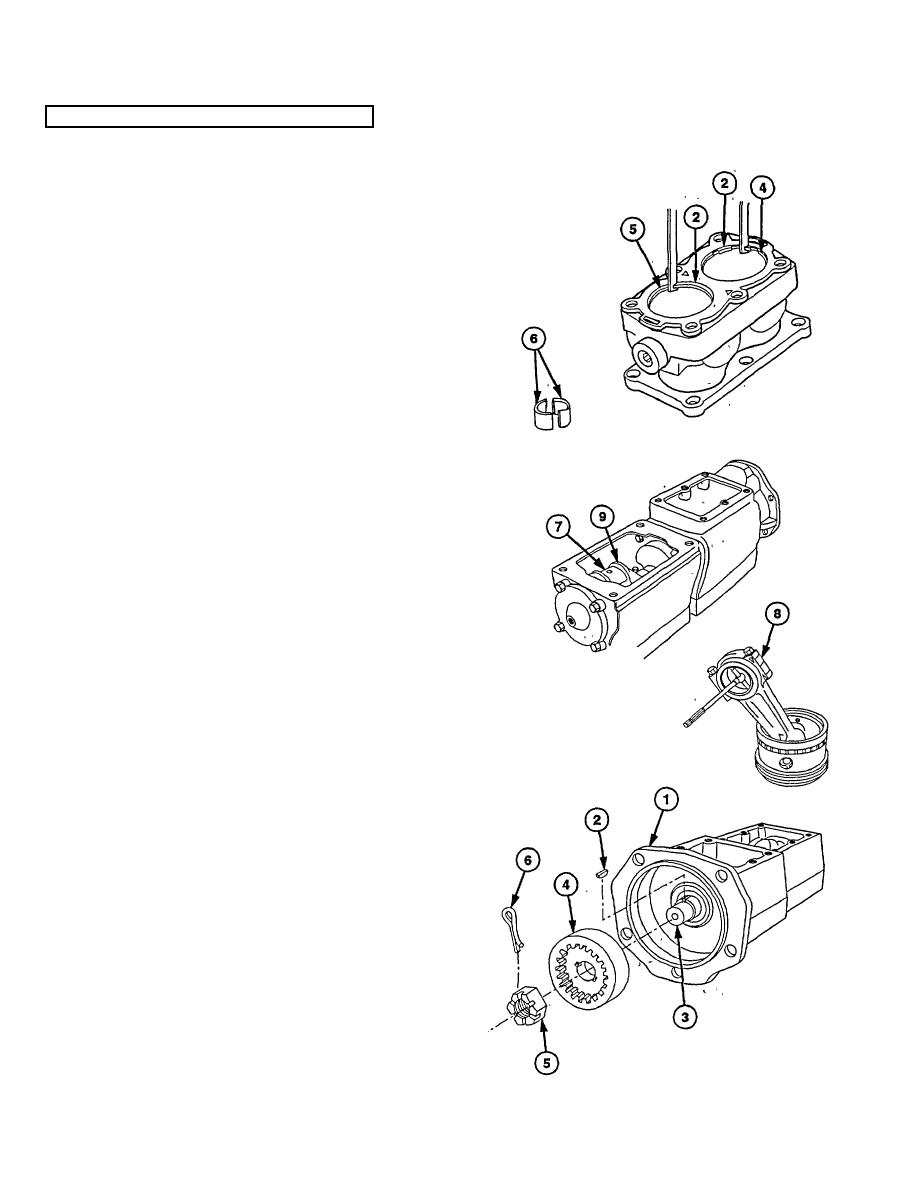

26-2. AIR COMPRESSOR REPAIR (CONT)

(13) Position compression ring (4) in cylinder

bore (2) and measure end gap clearance.

Replace rings if clearance exceeds 0.017

in. (0.43 mm).

(14) Position oil ring (5) in cylinder bore (2) and

measure end gap clearance. Replace

rings if clearance exceeds 0.055 in. (1.40

mm).

(15) Inspect connecting rod bearings (6) for

scoring, pitting, or visible wear. Clearance

between bearings (6) and crankshaft

journals (7) must be 0.005-0.0021 in.

(0.053-0.127

mm)

after

assembly.

Replace

bearings

if

clearance

is

exceeded.

(16) Measure distance between side of

connecting rod bearing cap (8) and

crankshaft (9).

Clearance must not

exceed 0.010 in.

(0.254 mm) after

assembly.

Replace connecting rod if

clearance is exceeded.

(17) Check ball bearings for worn or damaged

balls; rotate bearings by hand to detect

roughness. Replace crankcase assembly

if wear, roughness, or damage is evident.

(18) Coat parts with lubricating oil.

c. Assembly

(1) Position crankcase assembly (1) in vise.

(2) Install key (2) in crankshaft (3).

NOTE

When proper torque is reached,

continue to tighten until slot in nut

aligns with hole in crankshaft for

cotter pin.

(3) Install drive coupling (4) and nut (5) on

crankshaft (3). Torque to 80 lb-ft (108

N⋅m).

(4) Install new cotter pin (6) through nut (5)

and crankshaft (3).

26-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |