|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

b. Cleaning/Inspection

WARNING

Dry cleaning solvent P-D-680 is toxic and flammable. Wear protective goggles and

gloves and use only in well-ventilated area. Avoid contact with skin, eyes, and

clothing, and don't breathe vapors. DO NOT use near open flame or excessive

heat. The flash point Is 100-138 F (38-59 C). If you become dizzy while using

cleaning solvent, get fresh air immediately and medical aid. If contact with eyes is

made, wash your eyes with water and get medical aid immediately.

(1) Clean metal parts with dry cleaning solvent.

WARNING

Compressed air for cleaning purposes will not exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.).

(2) Dry parts with compressed air.

(3) Clean carbon deposits from cylinder head

interior surfaces, piston crowns, and

piston ring grooves.

(4) Clean interior air and water passageways

and blow out with compressed air.

(5) Remove gasket material from gasket

mating surfaces.

(6) Inspect cylinder heads, cylinder blocks,

and crankcase assembly for cracks and

damaged threads. Gasket surfaces must

be free of nicks and gouges.

(7) Inspect intake and exhaust valves for

wear grooves, cracks, or pits.

(8) Inspect pistons for scoring, cracks, or

other damage.

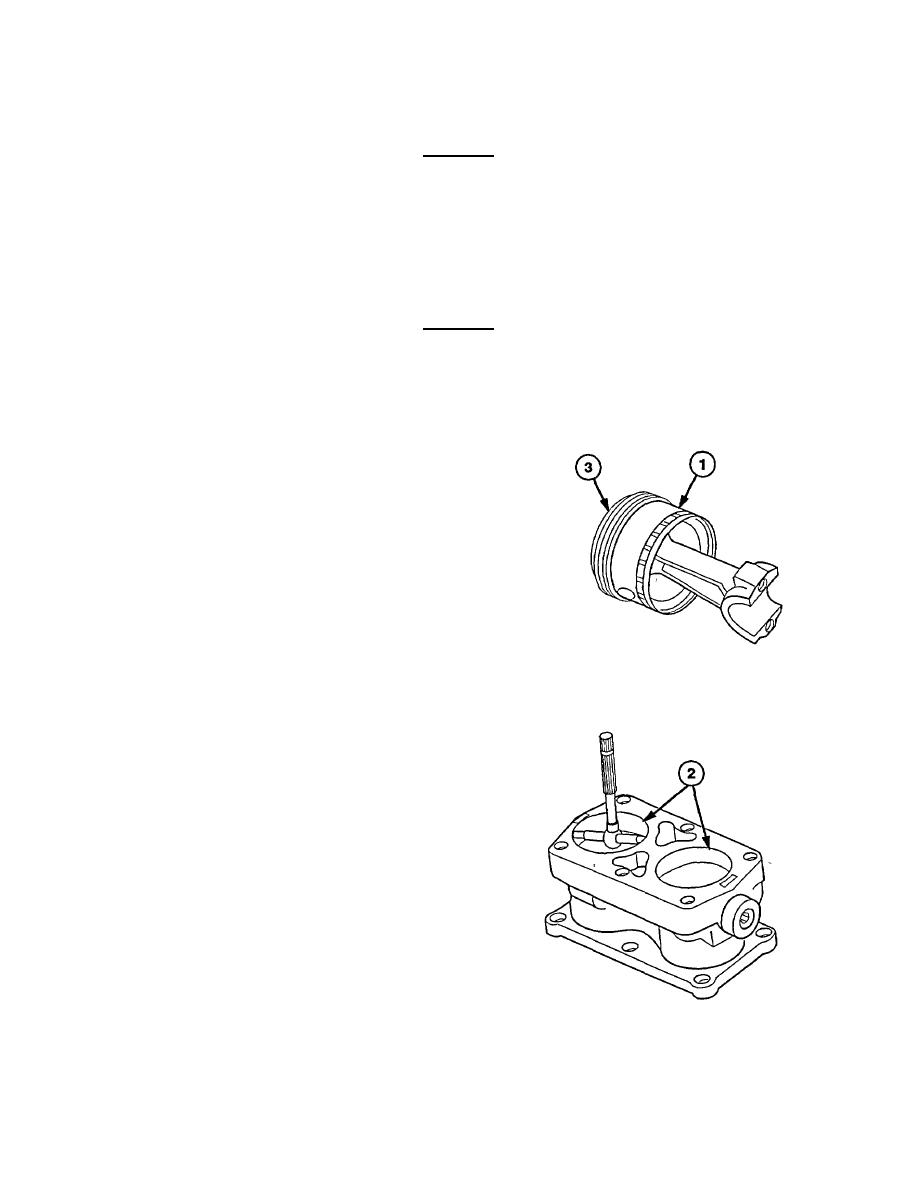

(9) Measure piston (1) outside diameter.

Measure cylinder bore (2) inside diameter

using telescoping gage. Piston (1) to bore

(2) clearance should not exceed 0.008 in.

(0.20 mm). Replace pistons and cylinder

block if clearance is exceeded.

(10) Inspect cylinder bores

for

scratches,

scoring, and pitting.

(11) Inspect bores (2) for out-of-round or taper.

Bores (2) must not be out-of-round more

than 0.0005 in. (0.013 mm). Bores (2)

must not taper more than 0.001 in. (0.025

mm) from top to bottom of bore. Replace

cylinder block if limits are exceeded.

(12) Inspect piston rings for cracks or wear.

Clearance between rings (3) and piston

(1) grooves must not exceed 0.0045 in.

(0.114 mm).

26-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |