|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

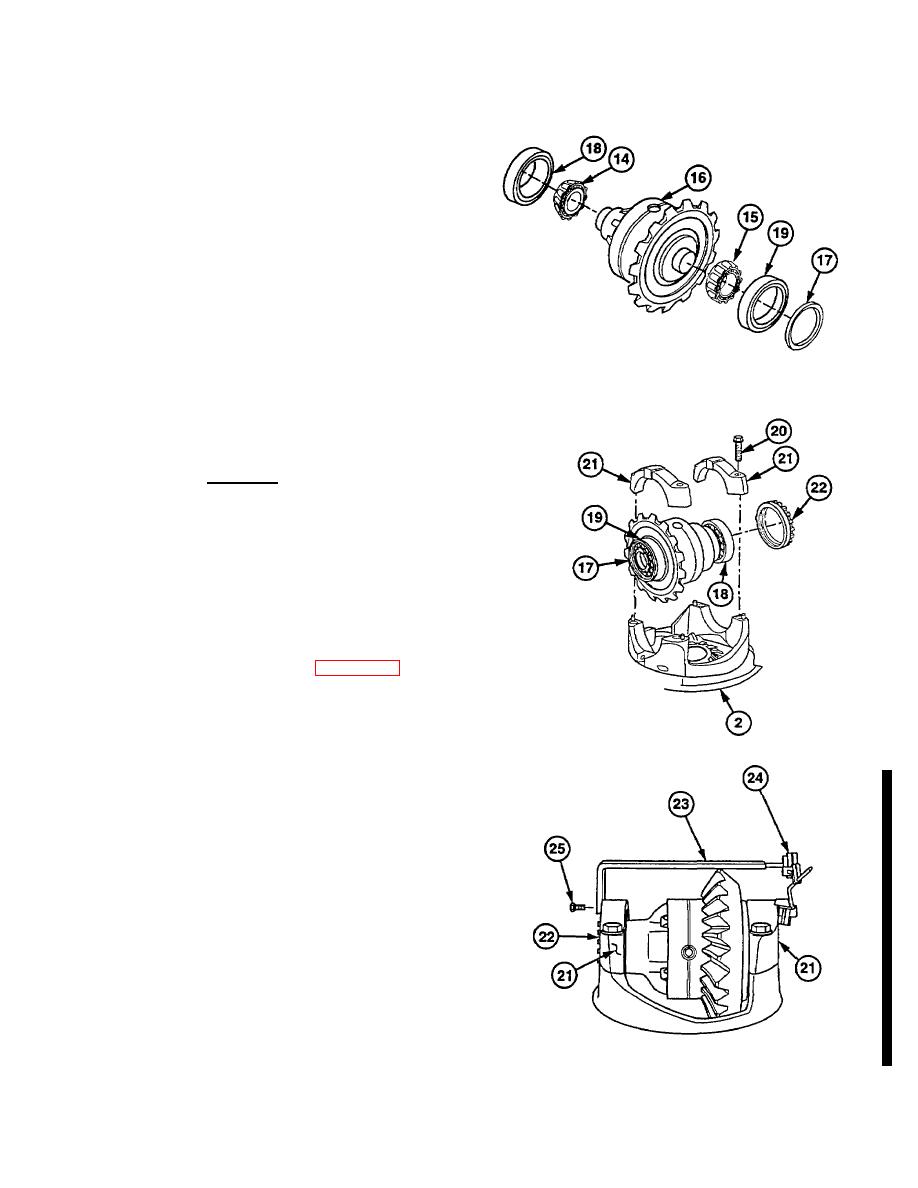

(13) Install taper bearings (14 and 15) on

differential (16).

NOTE

If thickness of pinion gear shims

increased, differential shim must be

decreased by same amount.

If

thickness of pinion gear shims

decreased, differential shim must be

increased by same amount. Refer to

TM

9-2320-360-34P

for

proper

identification of parts.

(14) Measure thickness of shim (17) and

change thickness if necessary.

(15) Install differential (16), bearing races (18

and 19), and shim (17) in differential

housing (2).

WARNING

Adhesive-sealant can burn easily,

can give off harmful vapors, and is

harmful to skin and clothing. To

avoid injury or death, keep away from

open fire and use in well ventilated

area. If adhesive-sealant gets on skin

or clothing, wash immediately with

soap and water.

(16) Coat threads of capscrews (20) with

adhesive-sealant (Item 4, Appendix B).

(17) Install two bearing caps (21) on housing

(2) with four capscrews (20). Torque to 25

lb-in. (2.82 Nm).

(18) Install adjusting nut (22) in bearing cap

(21).

(19) Install differential carrier preload gage (23)

on bearing cap (21) with screw (25).

(19.1) Position magnetic base of dial indicator

(24) on bearing cap (21).

(19.2) Position probe of dial indicator (24) on

differential carrier preload gage (23).

(19.3) Zero dial indicator (24).

(20) Tighten adjusting nut (22) until bearing

caps (21) expand 0.013-0.017 in. (.33-.43

mm).

(20.1) Remove screw (25), differential carrier

preload gage (23) and dial indicator (24)

from bearing caps (21).

(21) Tighten capscrews (20) to 125 Ib-ft (169

Nm).

Change 2 25-67

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |