|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

WARNING

Compressed air for cleaning purposes will hot exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.).

(3)

Dry all parts, except bearings, with compressed air. Allow bearings to air dry.

(4)

Inspect bearings for corrosion, scoring, pitting, or other damage.

(5)

Inspect all machined surfaces for nicks, burrs, or scratches. Remove defects with crocus cloth.

(6)

Inspect both case halves for cracks or damage.

(7)

Inspect all threads for peeled or crossed condition.

(8)

Replace all oil seals and damaged parts.

c.

Assembly

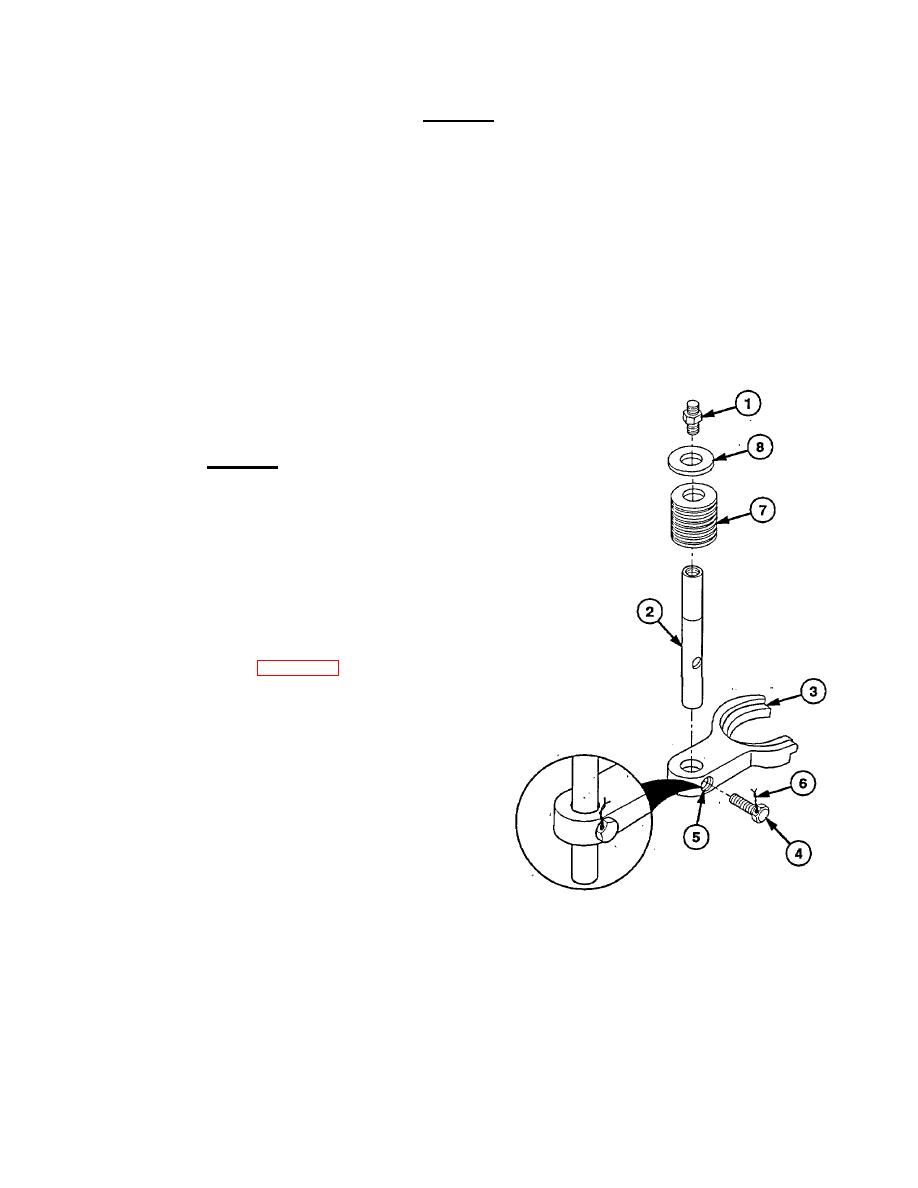

(1) Coat threads of stud (1) with grease.

(2) Install stud (1) in shift rod (2). Torque to

15 1b-ft (20 Nm).

(3) Slide shift rod (2) in fork (3).

WARNING

Adhesive-sealant can burn easily,

can give off harmful vapors, and is

harmful to skin and clothing. To

avoid injury or death, keep away from

open fire and use in well-ventilated

area. If adhesive-sealant gets on skin

or clothing, wash immediately with

soap and water.

(4)

Coat threads of screw (4) with adhesive-

sealant (Item 6, Appendix B).

(5)

Align holes (5) in fork (3) and shift rod (2)

and install screw (4). Torque to 40 lb-ft

(54 Nm).

(6)

Secure screw (4) with lockwire (6).

(7)

Install eight spring disks (7), alternating

concaved surfaces, in pairs, and spacer

(8) on shift rod (2).

23-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |