|

|||

|

|

|||

|

Page Title:

FORWARD CLUTCH AND TURBINE SHAFT REPAIR (CONT) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

c. Cleaning/inspection

WARNING

Dry cleaning solvent P-D-680 Is toxic

and flammable.

Wear protective

goggles and gloves and use only in a

well-ventilated area. Avoid contact

with skin, eyes, and clothes, and

don't breathe vapors. DO NOT use

near open flame or excessive heat.

The flash point is 100-138 F (38-

59 C). If you become dizzy while

using cleaning solvent, get fresh air

immediately and medical aid.

If

contact with eyes is made, wash your

eyes with Water and get medical aid

immediately.

(1) Clean metal parts with dry cleaning solvent and

inspect for damage. Replace damaged parts.

(2) Turbine shaft is pressed in forward clutch

housing and should be tight. Replace forward

clutch housing if there is any up and down

movement.

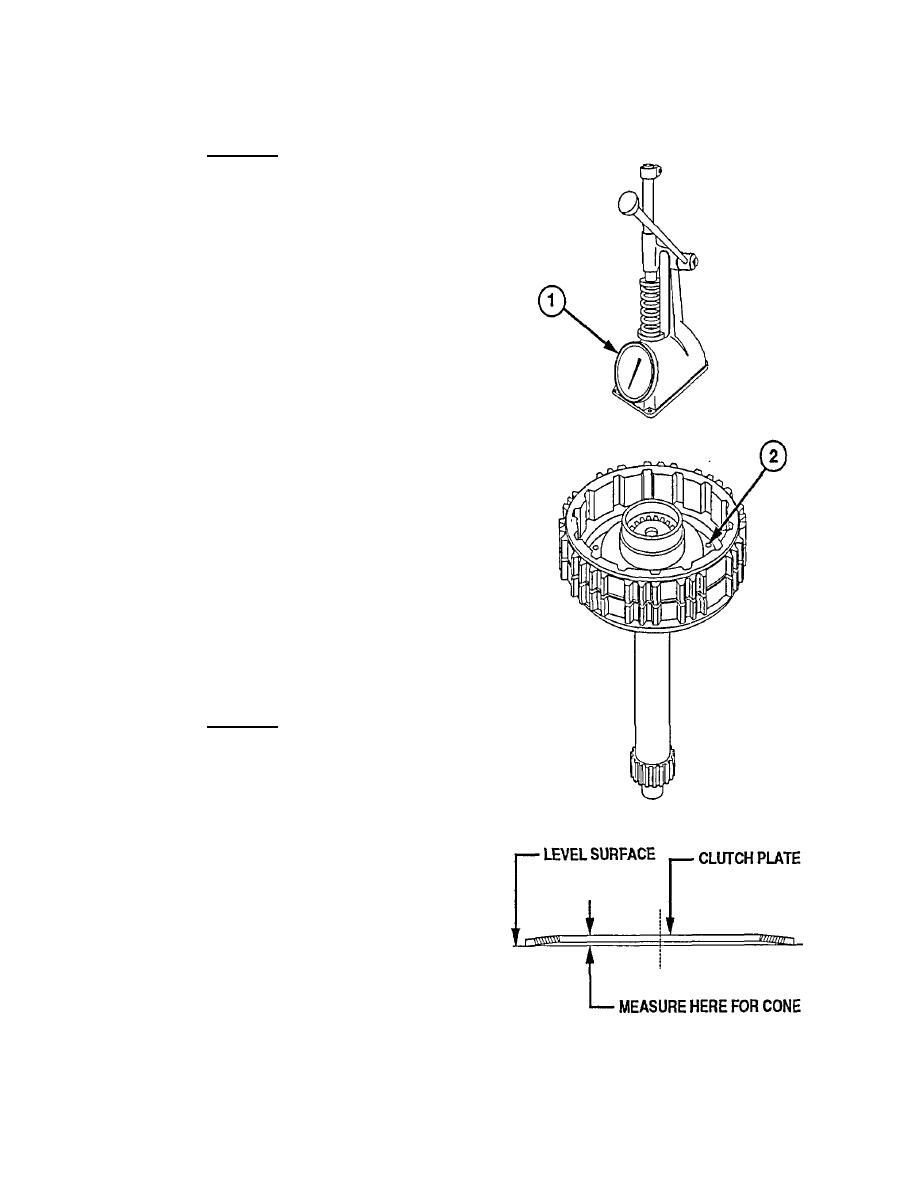

(3) Measure piston release spring lengths using

spring tester (1). Replace all 20 piston release

springs if any 3 do not meet the following load-

height requirements:

(a) Length without load: 1.25 in. (31.8 mm)

(b) Length under load: 0.88 in. (22.4 mm)

with load of 17.9-18.9 lb (8.13-8.58 kg).

(4) Clean ball pockets (2) with dry cleaning solvent.

WARNING

Compressed

air

for

cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding and personal protective

equipment (goggles/shield, gloves,

etc.).

(5) Inspect balls for freedom of movement and

proper staking. Replace balls if damaged.

(6) Dry pockets with compressed air.

Apply

lubricating oil around area of ball pockets (2).

(7) Measure individual clutch plate thickness by

measuring amount of cone. The amount of cone

is the distance between the inside' diameter and

level surface.

(a) Steel clutch plate:

Minimum thickness 0.0993 in. (2.522 mm)

(b) Friction plate:

Minimum thickness 0.090 in. (2.29 mm)

(c) Clutch driving hub (plate contact area):

Minimum thickness 0.390 in. (9.91 mm)

22-41

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |