|

|||

|

|

|||

|

Page Title:

TORQUE CONVERTER PUMP REPAIR (Cont.) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

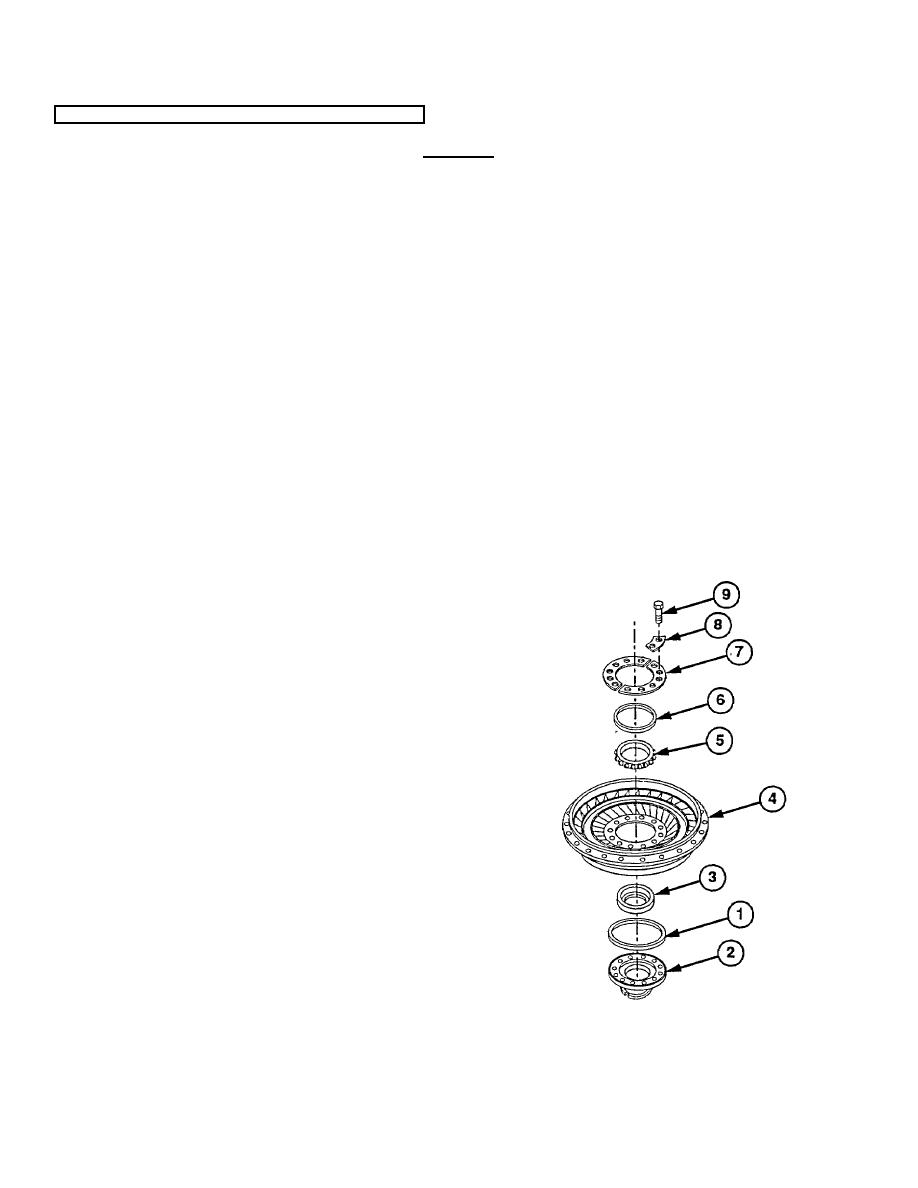

22-6. TORQUE CONVERTER PUMP REPAIR (CONT)

WARNING

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use

only with effective chip guarding and personal protective equipment (goggles,

shield, and gloves).

(2)

Dry metal parts, except bearings, with

compressed air.

(3)

Inspect parts for damage.

(4)

Replace damaged parts.

(5)

Coat parts with lubricating oil.

d.

Assembly

(1) Coat new seal ring (1) with lubricating oil

and install on torque converter pump hub

(2).

CAUTION

Ensure that two bearing races have

the same serial number.

(2)

Install inner race (3) on hub (2).

(3)

Install hub (2) on torque converter pump

(4).

CAUTION

Bearing must be kept clean during

installation. Keep bearing wrapped

until bearing is installed. Set bearing

on clean, lint-free paper and never on

dirty surface.

(4)

Install bearing (5) in inner race (3).

(5)

Install outer race (6) over bearing (5).

(6)

Install two bearing retainers (7) in groove

on outer race (6).

(7)

Position 6 new lockstrips (8) and 12

screws (9). Snug the screws at 12, 6, 3,

and 9 o'clock positions.

Snug the

remaining screws finger tight.

(8)

Tighten the four screws in the same

manner (12, 6, 3, and 9 o'clock) 35-40 lb

ft (47-54 Nm). Tighten the remaining

eight screws 35-40 lb ft (47-54 N m) with

aid of assistant.

(9)

Bend comers of lockstrips (8) against

heads of screws (9).

22-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |