|

|||

|

|

|||

|

Page Title:

FLYWHEEL ASSEMBLY/LOCKUP CLUTCH REPAIR (CONT) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

WARNING

Compressed

air

for

cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding and personal protective

equipment (goggles/shield, gloves,

etc.).

(2)

Dry all parts, except for bearings, with

compressed air.

(3)

Inspect all parts for damage. Replace all

damaged parts.

(4)

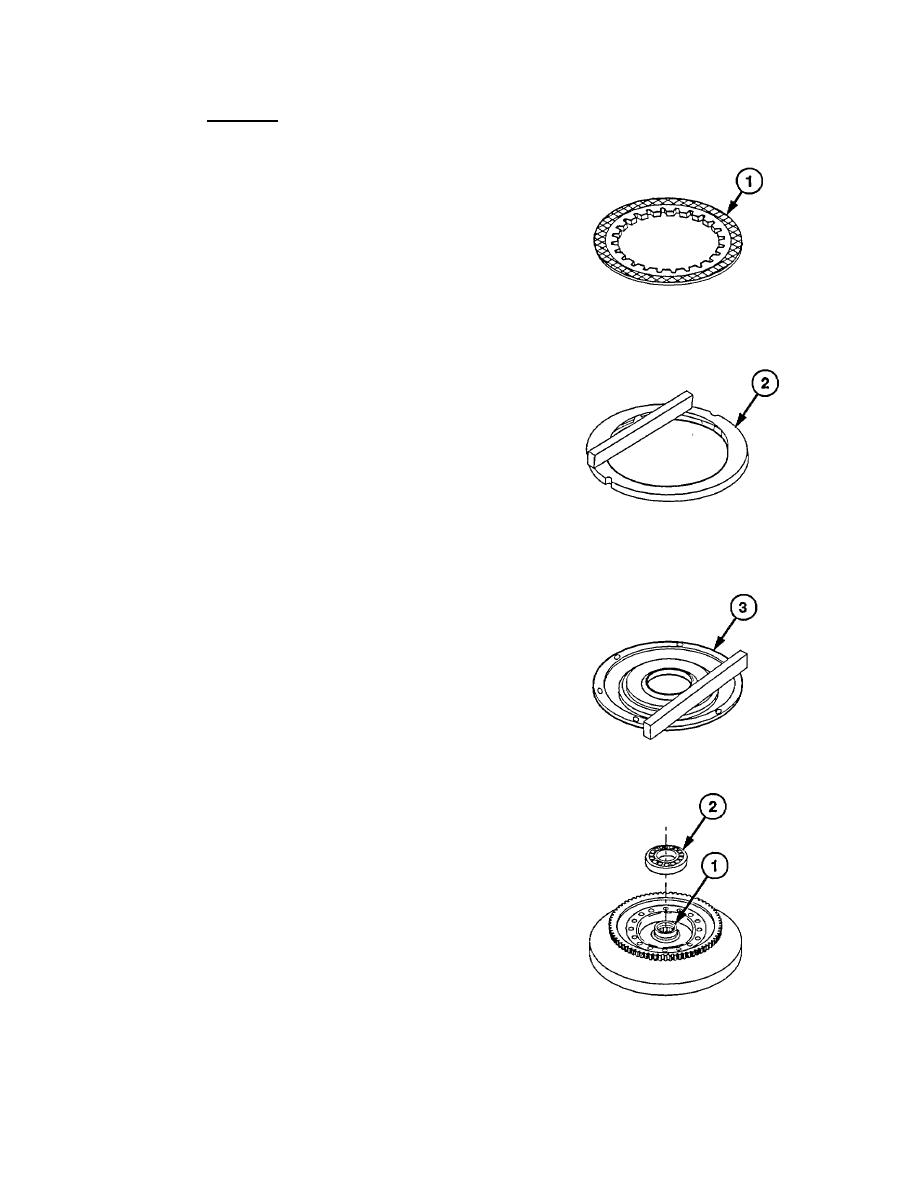

Measure thickness of lockup clutch plate

(1). Replace if less than 0.19 in. (4.83

mm) thick.

(5)

Place straight edge on backplate (2) and

insert feeler gage. Measure gap between

straight edge and backplate. If feeler

gage larger than 0.010 in. (0.25 mm) will

fit under straight edge, replace backplate.

(6)

Place straight edge on piston (3) and

insert feeler gage. Measure gap between

straight edge and piston. If feeler gage

larger than 0.010 in. (0.25 mm) will fit

under straight edge, replace piston.

d.

Assembly

(1) Coat bearing shaft (1) and bearing (2)

with lubricating oil.

(2) Position bearing (2) on bearing shaft (1)

and press bearing on shaft.'

22-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |