|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

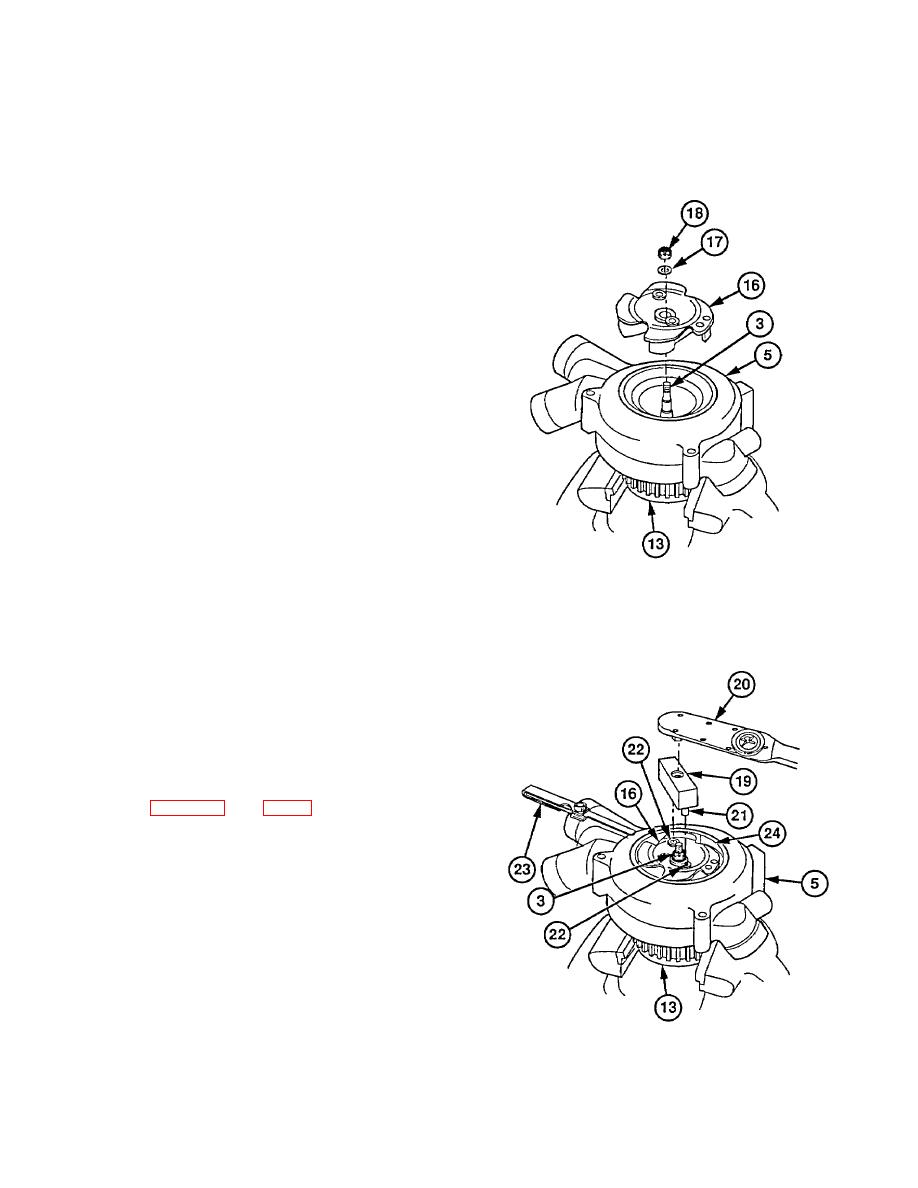

(14) Coat threads of shaft (3) with compound

no. 2.

(15) Place gear (13) in soft-Jawed vise.

(16) Install impeller (16) on shaft (3) with

washer (17) and new locknut (18).

Torque to 35-40 lb-ft (47-54 Nm).

NOTE

Steps (17) thru (21) measure slip

torque of gear.

(17) Scribe a line across gear (13) and shaft

(3).

(18) Scribe a second line across impeller (16),

locknut (18), and shaft (3).

(19) Install ad apter (19) on torque wrench (20).

(20) Insert adapter dowel pins (21) in impeller

puller holes (22) and apply torque of 80

lb-ft (108 Nm). Check assembly for

slippage while applying torque.

NOTE

If slippage was felt, examine scribed

marks to determine if gear or impeller

slipped and do step (21). Otherwise

go to step (22).

(21) Replace shaft (3) and component that

slipped (13 or 16). Repeat steps (17)

thru (20).

(22) Insert 0.015 in. (0.38 mm) feeler gage

(23) through water outlet opening

between impeller (16) and inside wall

(24) of water pump (5).

NOTE

If clearance in step (23) is wrong,

repeat para 21-2a and 21-2b.

(23) Turn impeller (16) while holding feeler

gage (23) in position to check clearance

between all blades of impeller (16) and

inside wall of water pump (5).

(24) Remove gear (13) from vise.

NOTE

Retaining ring, access cover, and

seal ring are installed in para 5-5.

21-7 (21-8 blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |