|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

21-2. WATER PUMP REPAIR

This task covers

a. Disassembly

c.

Assembly

b. Cleaning/Inspection

INITIAL SETUP

Equipment Conditions

Tools and Specials Tools (Cont)

Water pump on clean work surface.

Vise, Machinist's (Item 207, Appendix E)

Wrench, Torque, 0-175 Lb-Ft (Item 236,

Tools and Specials Tools

Tool Kit, Genl Mech (Item 202, Appendix E)

Adapter, Impeller, Slip Test (Item 1,

Materials/Parts

Adhesive-Sealant (Item 7, Appendix B)

Gage, Feeler (Item 50, Appendix E)

Compound, International No. 2 (Item 21,

Goggles, Industrial (Item 57, Appendix E)

Handle, Drive (Item 65, Appendix E)

Compound, Sealing, Pipe Thread (Item 28,

Installer, Oil Seal (Item 80, Appendix E)

Installer, Water Pump Drive Gear (Item 88,

Oil, Lubricating (Item 45, Appendix B)

Solvent, Dry Cleaning (Item 54, Appendix B)

Installer, Water Pump Seal (Item 89,

Tags, Identification (Item 56, Appendix B)

Repair Kit, Water Pump (Item 230, Appendix F)

Pliers, Retaining Ring (Item 108, Appendix E)

Ring, Retaining (Item 244, Appendix F)

Pliers, Retaining Ring (Item 110, Appendix E)

Press, Hydraulic (item 116, Appendix E)

Personnel Required

Puller Kit, Mechanical, Gear and Brg

Two

(Item 124, Appendix E)

a. Disassembly

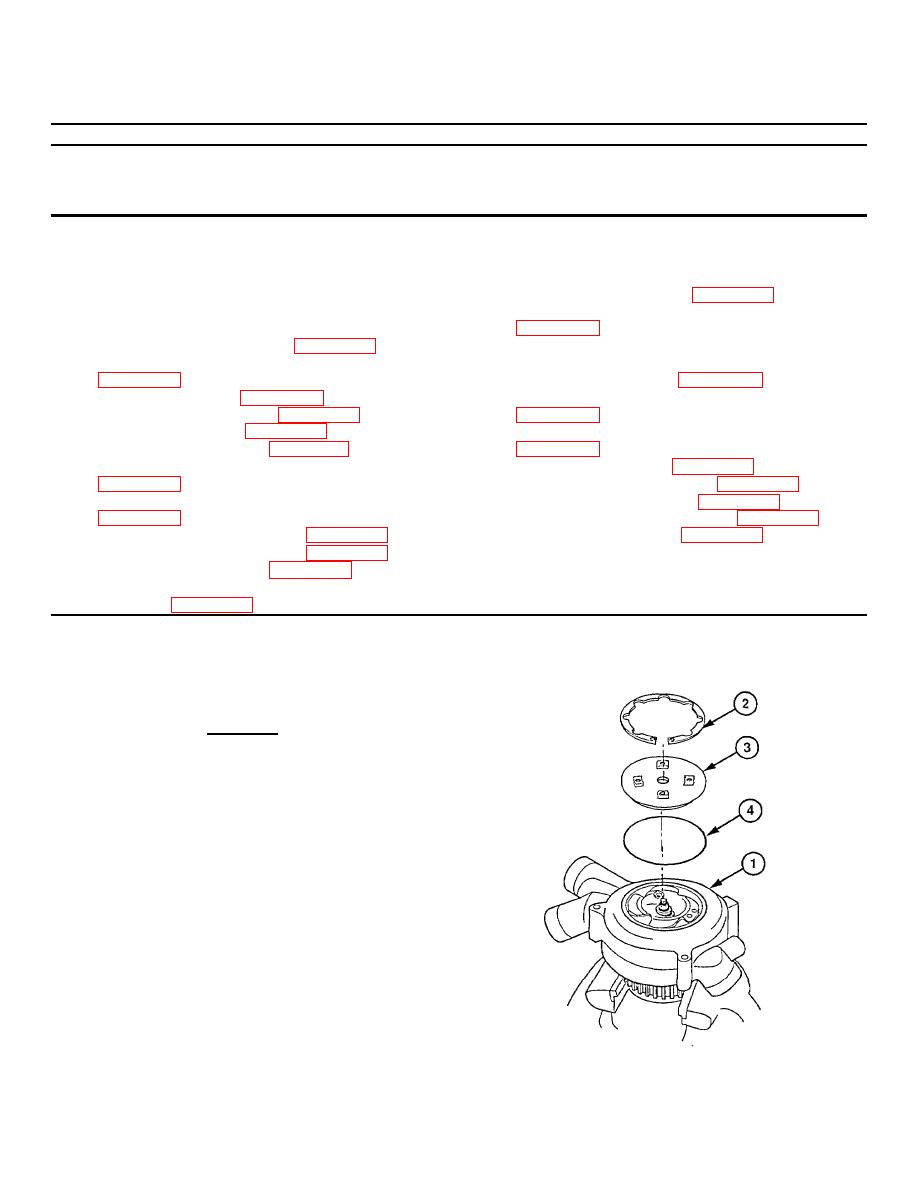

(1) Place water pump (1) gear-side down in

soft-jawed vise.

WARNING

Wear eye protection and use care

when removing retaining rings.

Retaining rings are under spring

tension and can act as projectiles

when released and may cause

severe eye Injury.

Due to size and tension of

retaining ring In step (2), ensure

suitable retaining ring pliers are

used for safety. Press a hammer

against pump cover to help

prevent Injury should retaining

ring slip off pliers.

(2) Remove retaining ring (2), access cover

(3), and seal ring (4) using retaining ring

pliers. Discard retaining ring and seal

ring.

21-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |