|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

20-2. BLOWER REPAIR (CONT)

WARNING

Compressed air for cleaning purposes will not exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.).

(3) Dry all metal parts, except bearings, with

compressed air. Allow bearings to air dry.

(4) Inspect roller and ball bearings for corrosion,

scoring, pitting, or other damage.

(5) Inspect both timing gears at teeth and bore

splines for chips or nicks.

(6) Inspect oil holes.

If clogged, clean with dry

cleaning solvent.

(7) Inspect all finished surfaces for burrs and

scoring. Clean with crocus cloth.

c. Assembly

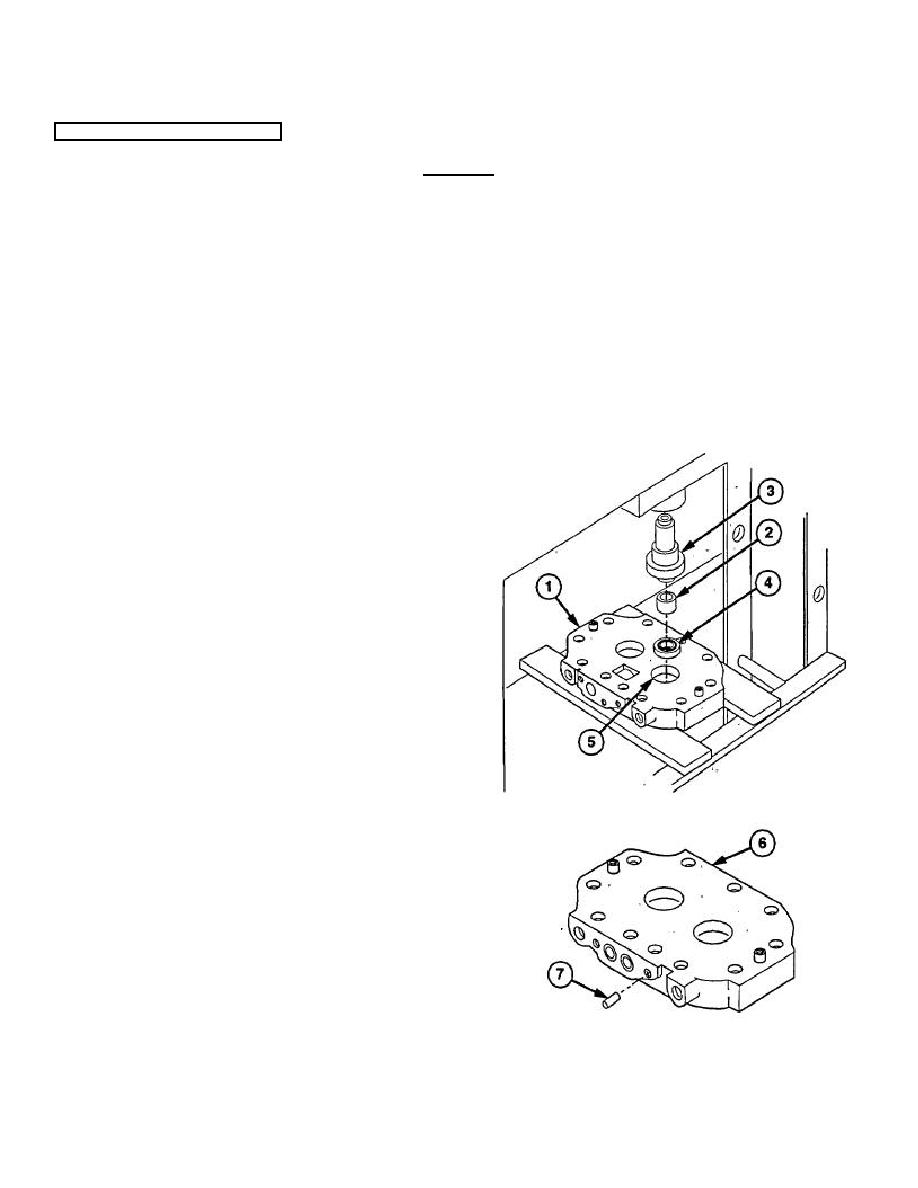

(1) Place rear end plate (1) on wooden blocks with

inner surface up.

(2) Install seal protector (2) on remove r and installer

tool (3).

CAUTION

Double-lipped oil seal must be

installed dry. Do not apply oil to seal

when installing.

Oil will damage

protective coating of seal.

(3) Install new double-lipped oil seal (4), number

side up, on tool. Press new oil seal (4) in bore

(5) until tool contacts rear end plate (1).

(4) Repeat steps (1) thru (3) to install remaining

seal in rear end plate (1) and two seals (4) in

front end plate (6).

(5) Install two pipe plugs (7) on front end plate (6).

20-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |