|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

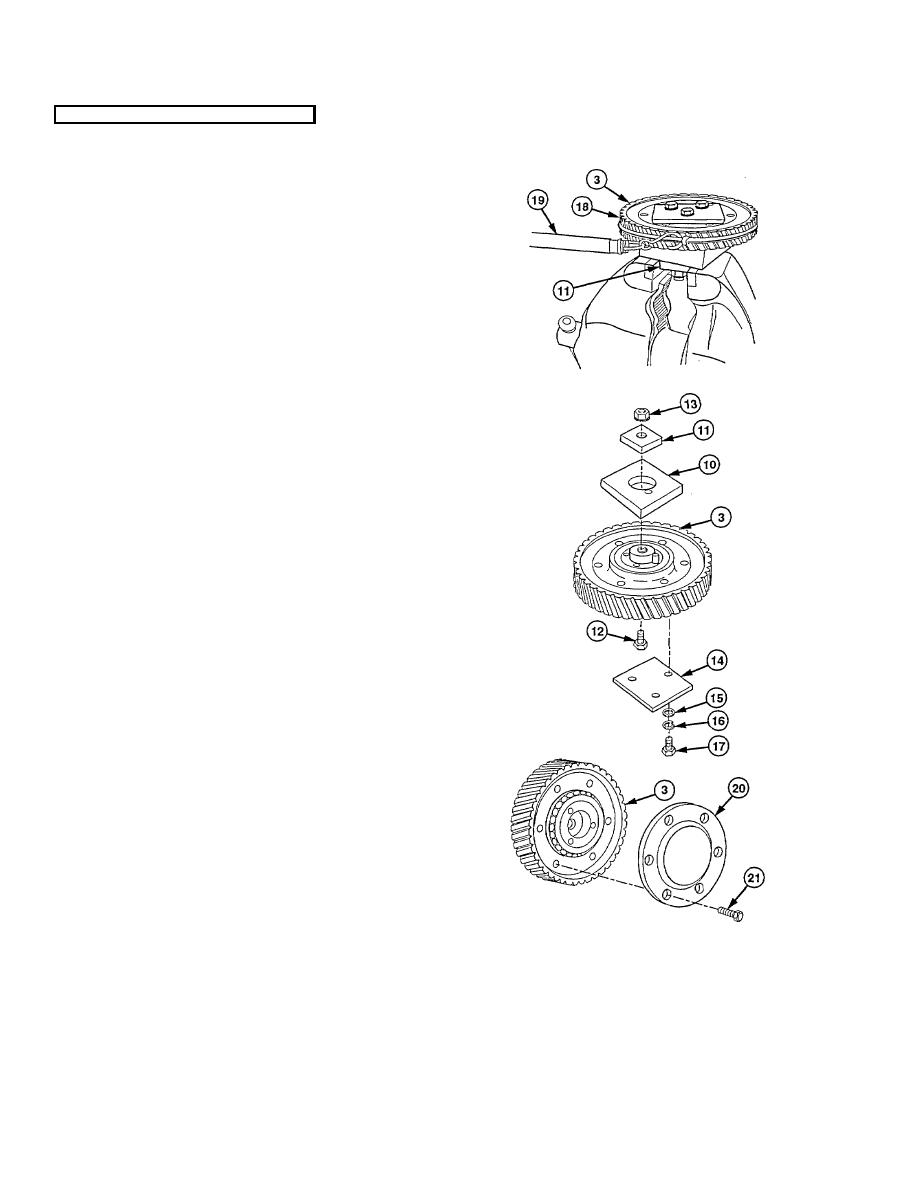

19-13. IDLER GEAR REPAIR (CONT)

(21) Place plate (11) in jaws of vise.

(22) Install two plastic ties (18) around outside

edge of idler gear (3) and tighten.

(23) Position spring gage (19) hook between

tie strap and idler gear (3).

NOTE

Pull to start gear moving must not

be less than 0.5 lb (0.23 kg) or

more than 4.0 lb (1.8 kg).

If scale reading is more than

specified maximum, rollers are

binding or improperly installed.

If scale reading is less than

specified minimum, bearings are

worn.

(24) Pull spring gage (19) several times and

record pull required to start gear (3)

moving.

Maximum difference between

pulls is 2 lb, 11 oz (1.22 kg).

(25) Remove spring gage (19) and plastic ties

(18) from idler gear (3).

(26) Remove three screws (17), lockwashers

(16), washers (15), and test fixture plate

(14).

(27) Place idler gear assembly (3) in soft-jawed

vise.

(28) Remove nut (13), screw (12), and two test

fixture plates (10 and 11).

(29) Remove idler gear assembly (3) from vise.

(30) Install retainer (20) on idler gear assembly

(3) with six new nylon patch screws (21).

Torque to 30 lb-ft (41 Nm).

19-118

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |