|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

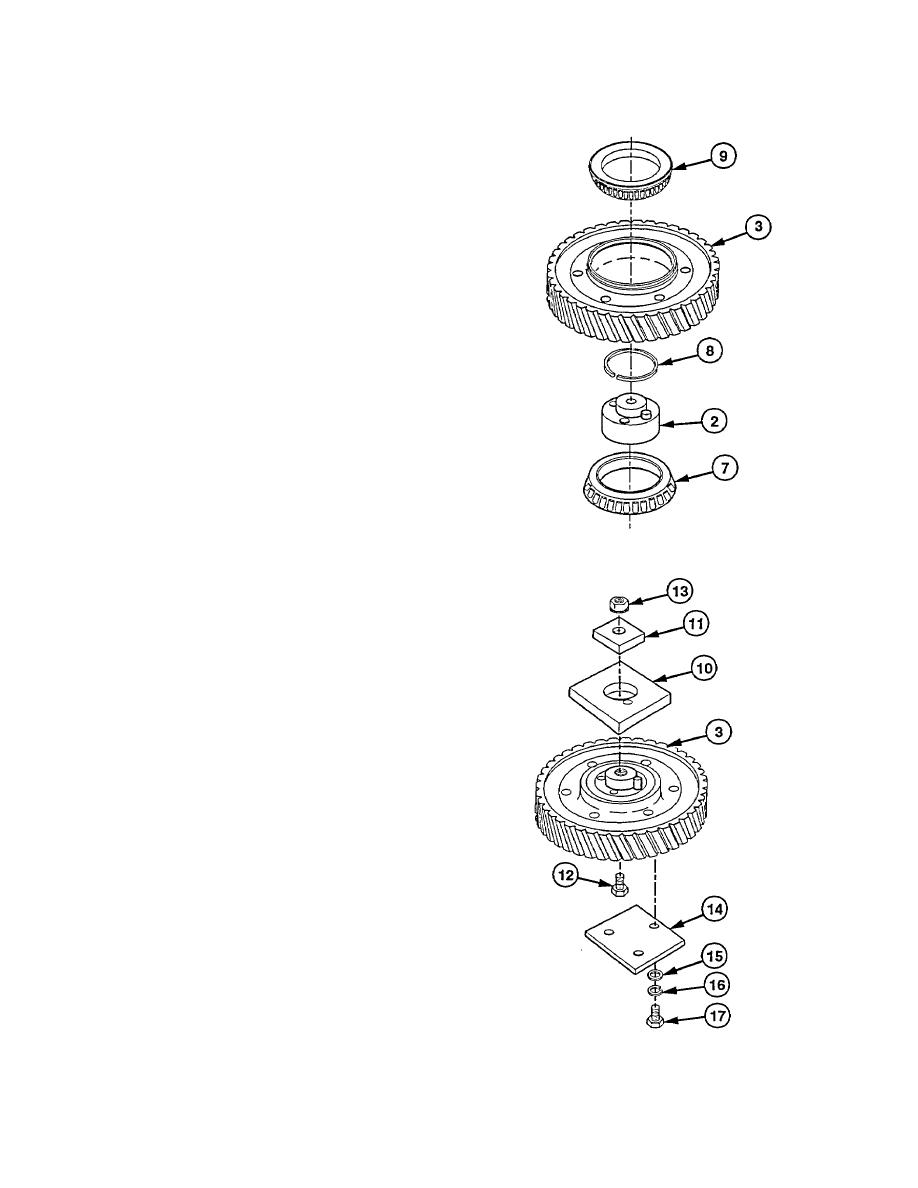

(8) Coat all parts with lubricating oil.

(9) Position outer bearing cone (7), numbered

side down, on bed of press.

(10) Press idler gear hub (2) in outer bearing

cone (7) until bottom of hub (2) Is flush

with bottom of cone (7).

(11) Install inner spacer ring (8) on idler gear

hub (2).

(12) Position gap in spacer ring (8) on side

opposite of oil hole in idler gear hub (2).

(13) Support outer bearing cone (7) and idler

gear hub (2).

(14) Position idler gear assembly (3) on idler

gear hub (2).

(15) Position inner bearing cone (9) on idler

gear assembly (3).

CAUTION

Turn gear while installing bearing

cone on idler gear hub to prevent

damage to bearing cups.

(16) Turn idler gear assembly (3) while

pressing

Inner

bearing

cone

(9),

numbered side up, over hub (2).

(17) Hold hub (2) and turn gear assembly (3) to

see if binding occurs.

NOTE

To check idler gear preload, do steps

(18) thru (28).

(18) Mount idler gear (3) In soft-jawed vise.

CAUTION

Hollow pin on idler gear hub must be

aligned with hole in test fixture plate.

Failure to comply may press pin Into

Idler gear hub.

(19) Mount two test fixture plates (10 and 11)

on idler gear (3) with screw (12) and nut

(13). Torque to 90 Ib-ft (122 Nm).

(20) Mount test fixture plate (14) on idler gear

(3) with three washers (15), lockwashers

(16), and screws (17). Torque to 40 lb-ft

(54 Nm).

19-117

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |