|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

19-13. IDLER GEAR REPAIR (CONT)

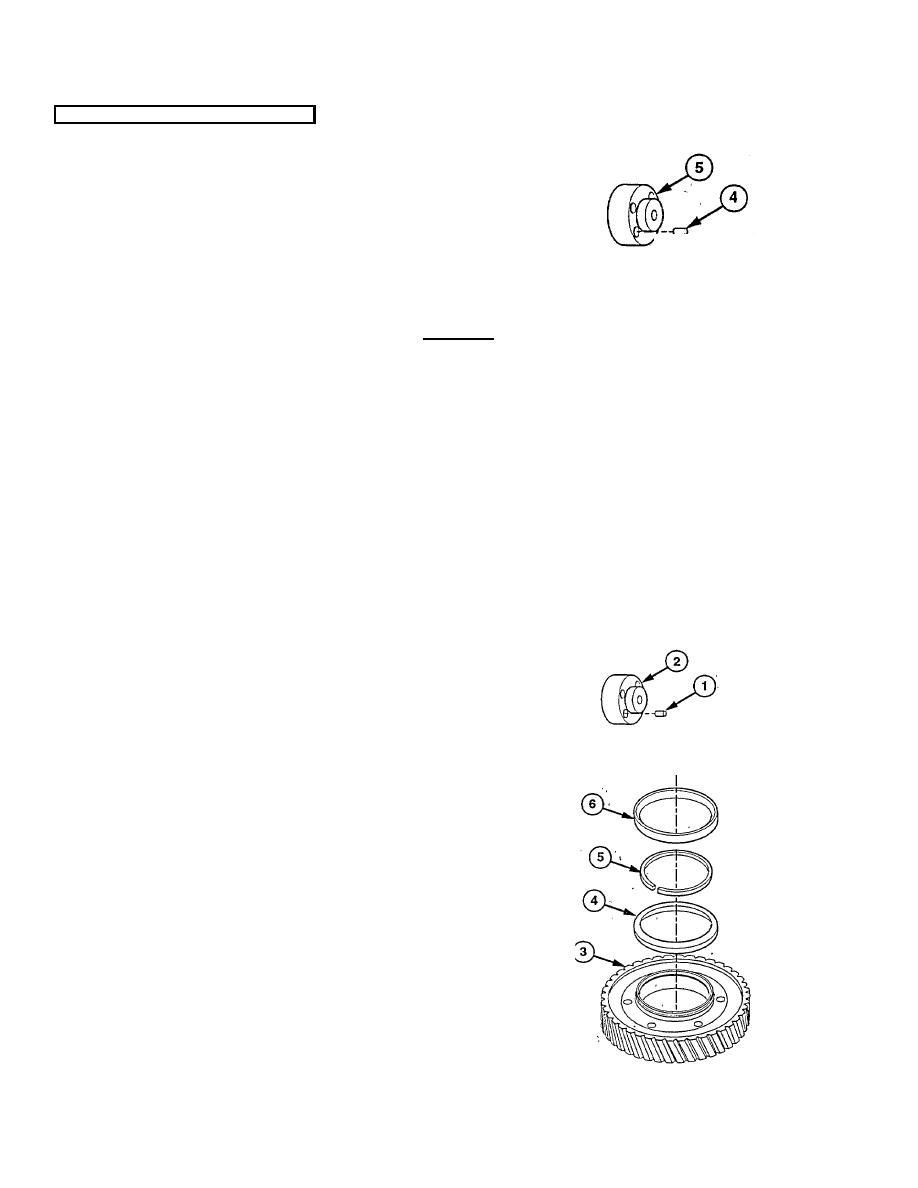

(8) Remove hollow pin (4) from idler gear hub

(5).

c. Cleaning/Inspection

WARNING

Dry cleaning solvent P-D-680 is toxic and flammable. Wear protective goggles and

gloves and use solvent only in a well-ventilated area. Avoid contact with skin,

eyes, and clothes, and don't breathe vapors. Do not use near open flame or

excessive heat. The flash point Is 100-138 F (38-59 C). If you become dizzy while

using cleaning solvent, get fresh air Immediately and get medical aid. If solvent

contacts eyes, wash eyes with water and get medical aid immediately.

(1) Clean idler gear and bearing parts with dry cleaning solvent.

(2) Inspect bearing for scoring, pitting, or flat spots on rollers or cones.

(3) Inspect bearing cups for scoring, pitting, and dents in bearing surface.

(4) Examine gear teeth for scoring, pitting, and chips.

(5) Replace all damaged parts.

(6) Coat all parts with lubricating oil.

d. Assembly.

(1) Install hollow pin (1) on idler gear hub (2).

NOTE

Bearing cones and cups are matched

sets. If any part is unusable, all parts

must be replaced.

(2) Support idler gear (3), shoulder down, on

bed of press.

(3) Coat inner bearing cup (4) with lubricating

oil.

Insert inner bearing cup (4),

numbered side up, in bore of gear (3).

(4) Press inner bearing cup (4) to seat against

shoulder of gear (3).

(5) Install outer spacer ring (5) on inner

bearing cup (4).

(6) Coat bearing cup (6) with lubricating oil.

Insert outer bearing cup (6), numbered

side down, in bore of gear (3).

(7) Press outer bearing cup (6) to seat

against shoulder of gear (3).

19-116

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |