|

|||

|

|

|||

|

Page Title:

PISTON, CONNECTING ROD, AND LINER REPAIR (cont.) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

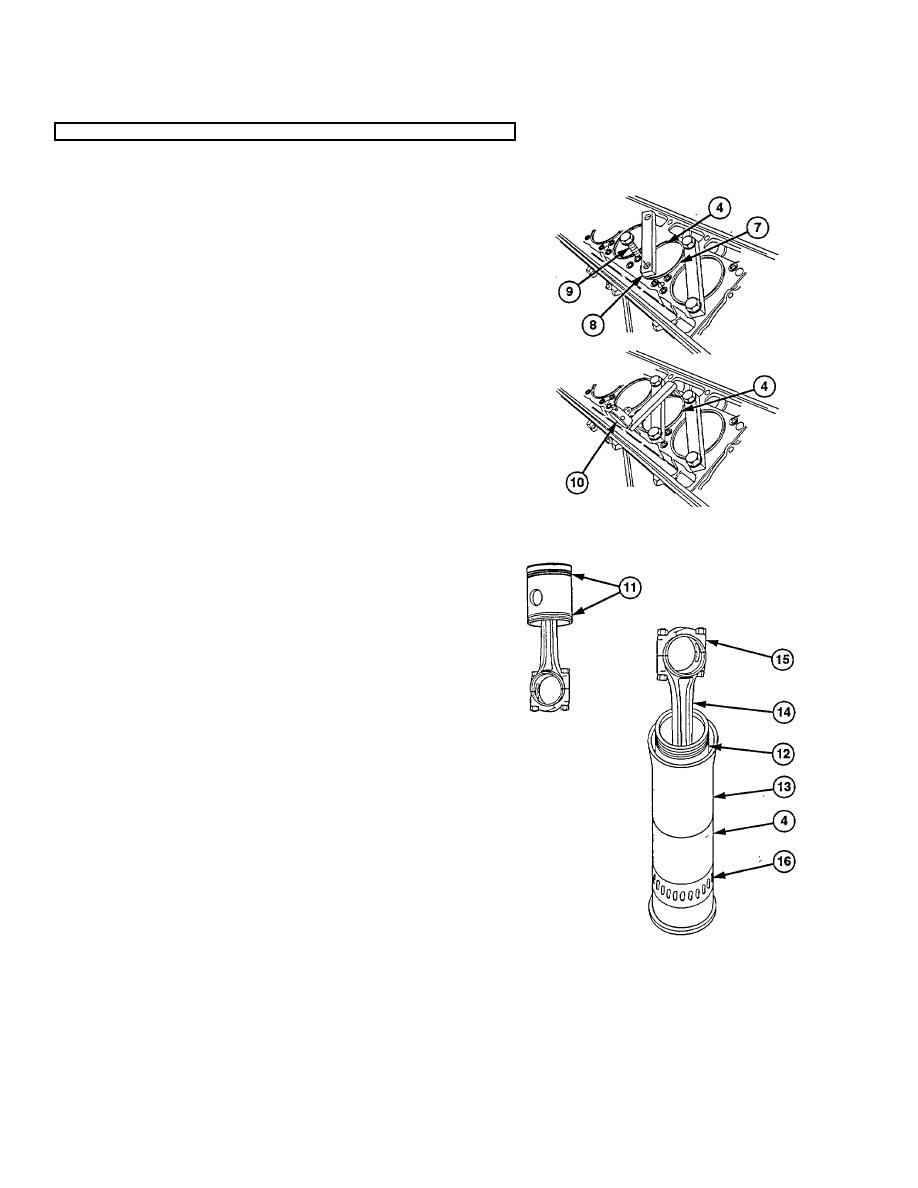

19-10. PISTON, CONNECTING ROD, AND LINER REPAIR (CONT)

(b) Clamp liner (4) in place with hold

down clamp (8) and two screws (9).

Torque to 50 Ib-ft (68 Nm).

(c) Measure distance from top of liner

(4) to top of block with cylinder liner

depth gage (10). Liner flange must

be 0.0418-0.0482 in.

(1.06-1.22

mm) below surface of block. Even

though all liners are within these

specifications, there must not be

over 0.0015 in.

(0.038 mm)

difference between two adjacent

liners

when

measured

along

cylinder longitudinal centerline. If

above limits are not met, install

different thickness insert, install liner

in another cylinder bore, and

recheck or use new cylinder liner.

(d) Remove screws (9), hold down

clamp (8), and cylinder liner (4). Do

not remove liner insert (7).

(5) Coat piston rings (11) with lubricating oil.

(6) Install piston (12) in ring compressor (13).

(7) Coat inside of cylinder liner (4) with

lubricating oil.

(8) Hold cylinder liner (4) flange end down on

wooden blocks. Place ring compressor

(13) with piston and connecting rod (14)

on cylinder liner (4).

NOTE

Matchmarks align cylinder liner and

engine block.

(9) Align numbers on connecting rod (14) and

rod bearing cap (15) with matchmark on

cylinder liner (4).

(10) Push piston into cylinder liner (4) until

compression rings pass cylinder liner

ports (16).

(11) Remove ring compressor (13) from

cylinder liner (4).

19-92

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |