|

|||

|

|

|||

|

Page Title:

PISTON, CONNECTING ROD, AND LINER REPAIR (cont.) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

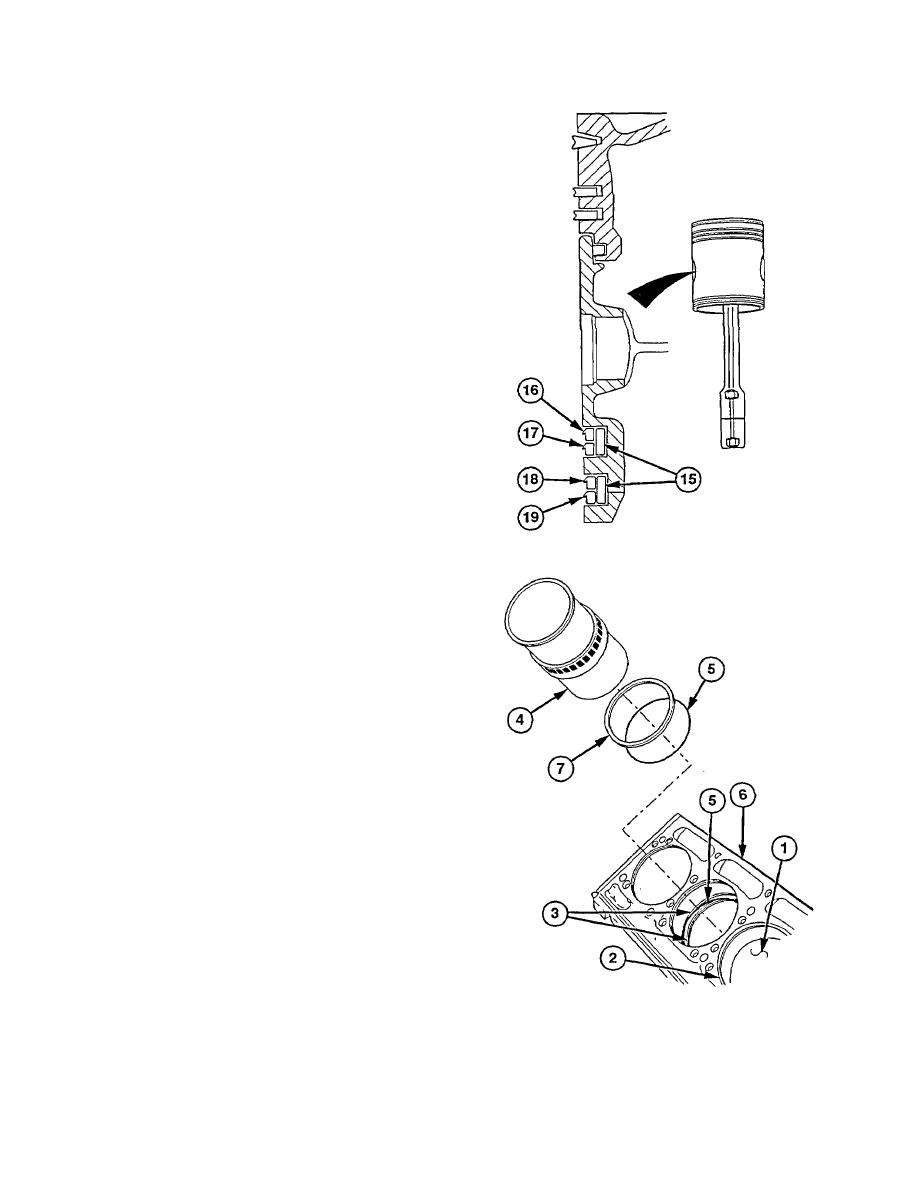

NOTE

Install oil rings with beveled edge

facing piston crown.

Top oil ring has chrome beveled

edge.

Both lower oil rings have

notches.

(26) Install new chrome and orange oil ring

(16) with gap positioned 180 degrees from

gap in expander ring (15).

(27) Install new black and orange oil ri ng (17)

with gap positioned 90 degrees from gap

In oil ring (16).

(28) Install new oil ring (18) with notched side

toward connecting rod and gap positioned

180 degrees from gap positioned in

expander ring (15).

(29) Install new oil ring (19) with notched side

toward connecting rod and gap positioned

90 degrees from gap in oil ring (18).

e. Installation

(1) Wipe cylinder bore (1), counterbore (2),

seal rings grooves (3), and cylinder liner

(4) clean.

(2) Install two new cylinder liner seal rings (5)

in engine block (6).

(3) Coat Inner surface of cylinder seal rings

(5) with lubricating oil.

(4) Install previously tagged liner insert (7) in

counterbore (2) of engine block (6).

(a) Push cylinder liner (4) in cylinder

block until liner flange rests on insert

(7). Do not use excessive force to

install liner.

Liner should slide

smoothly in place. Gently seat with

soft-faced mallet.

19-91

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |