|

|||

|

|

|||

|

Page Title:

PISTON, CONNECTING ROD, AND LINER REPAIR (cont.) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

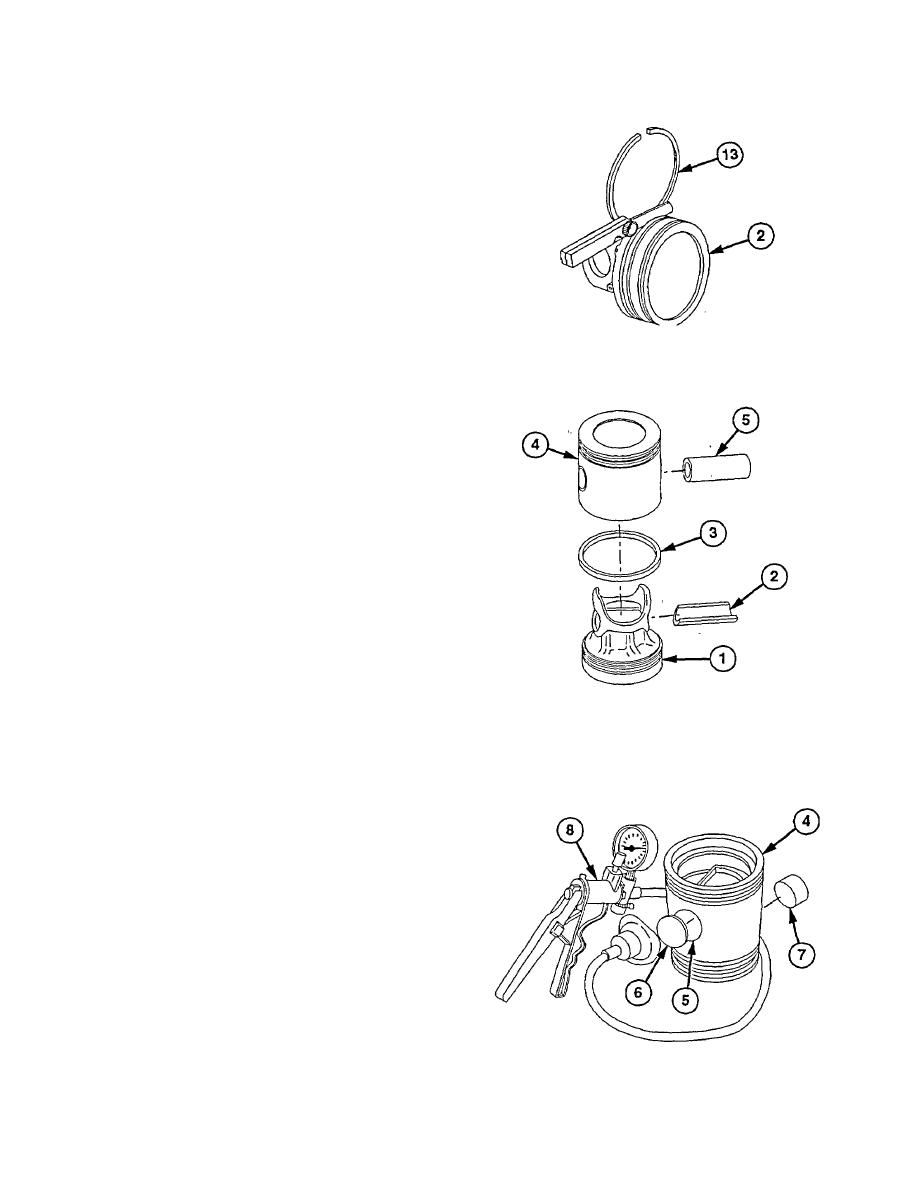

(16) Insert new lower compression ring (13) in

lower groove on side of piston crown (2);

clearance should be 0.004-0.007 in. (0.10-

0.18 mm).

d. Assembly

(1) Place piston crown (1) top end down on

work bench.

(2) Install new piston pin bearing (2) in piston

crown (1).

(3) Coat new rubber seal ring (3) with

lubricating oil.

(4) Install rubber seal ring (3) on piston crown

(1).

(5) Push piston skirt (4) down into position on

piston crown (1).

(6) Coat piston pin (5) with lubricating oil.

(7) Align hole in piston skirt (4) with hole in

piston crown (1).

(8) Install piston pin (5) with threaded holes

toward bottom of piston skirt (4).

(9) Place piston crown (1) and skirt (4) in soft-

jawed vice.

NOTE

Place domed end of retainer tool

against retainer.

Strike tool just hard enough to

defect retainer and seat evenly in

piston.

(10) Install piston pin retainers (6) in piston

skirt (4) at each side of piston pin (5) using

piston pin retainer tool (7).

(11) Use leak detector (8) to apply 10 in. (254

mm) of vacuum to each piston pin retainer

(6). There should be no loss of pressure.

(12) If loss of pressure occurs, repeat steps

(10) and (11).

(13) Remove piston crown (1) and skirt (4)

from vise.

19-89

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |