|

|||

|

|

|||

|

Page Title:

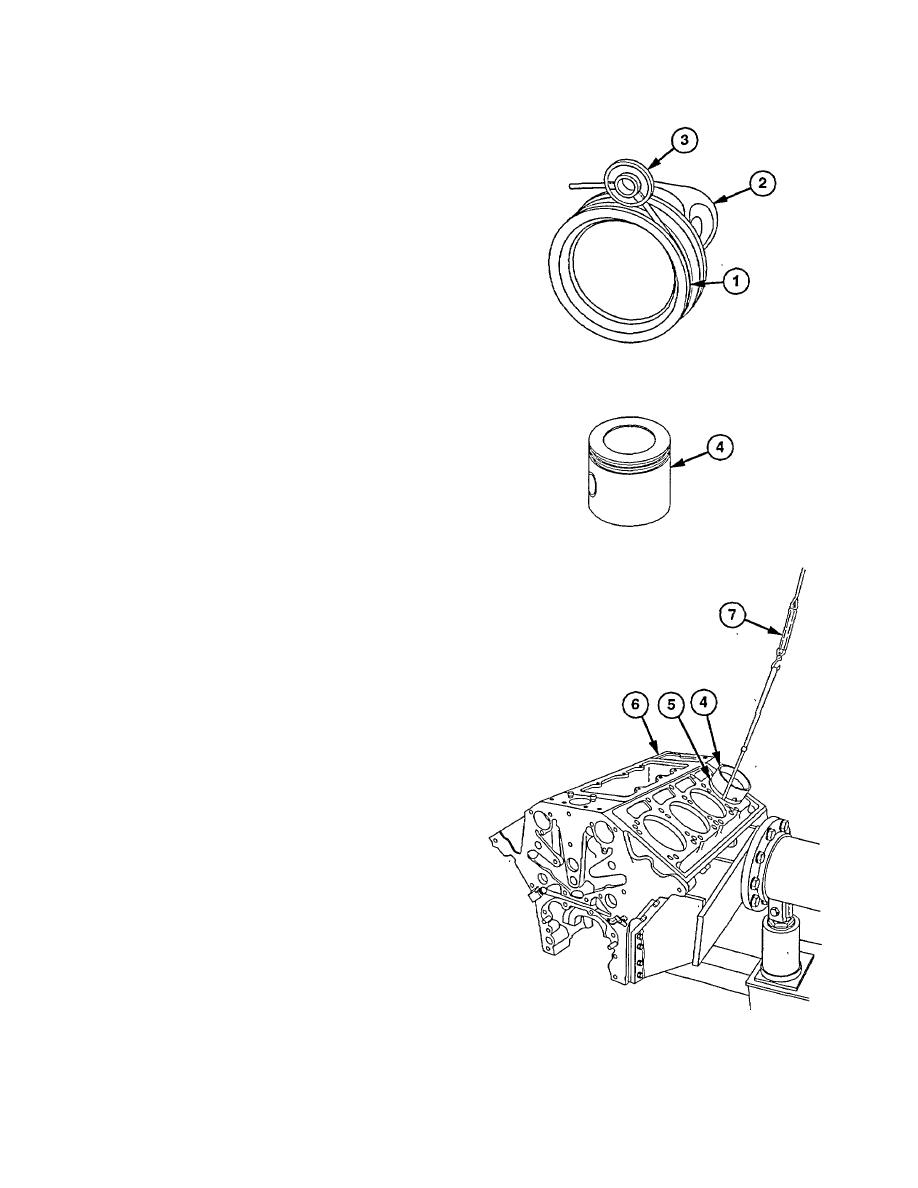

PISTON, CONNECTING ROD, AND LINER REPAIR (cont.) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

NOTE

Piston crown, bearing, and pin must

be replaced as an assembly.

(6) Slide NO-GO wire of piston groove gaga

tool (3) completely around groove (1). If

wire is below flush at any one area,

replace crown (2).

(7) Slide GO wire of groove gage tool (3)

completely around groove (1).

Wire

should be flush with or slightly higher than

top edge of groove.

(8) Measure diameter of piston skirt (4) and

check for roundness using micrometer.

Diameter must be between 4.8304 and

4.8314 in. (122.69 and 122.72 mm).

NOTE

Piston skirt is installed upside down

in liner.

(9) With cylinder liner (5) installed on engine

block (6), Install piston skirt (4) and feeler

gage in liner (5) at same time. Have

assistant attach piston gage set (7) and

check clearance in four places 90 degrees

apart.

NOTE

Feeler gage size is determined by

amount of wear in piston skirt and

liner.

(10) Select largest feeler gage thickness that

will require a pull of less than 6 lb (2.7 kg).

Clearance will be 0.001 in. (0.25 mm)

greater than feeler gage thickness when it

is withdrawn with a pull of 6 lb (2.7 kg).

Clearance must be between 0.007 and

0.011 in. (0.18 and 0.28 mm).

19-87

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |