|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

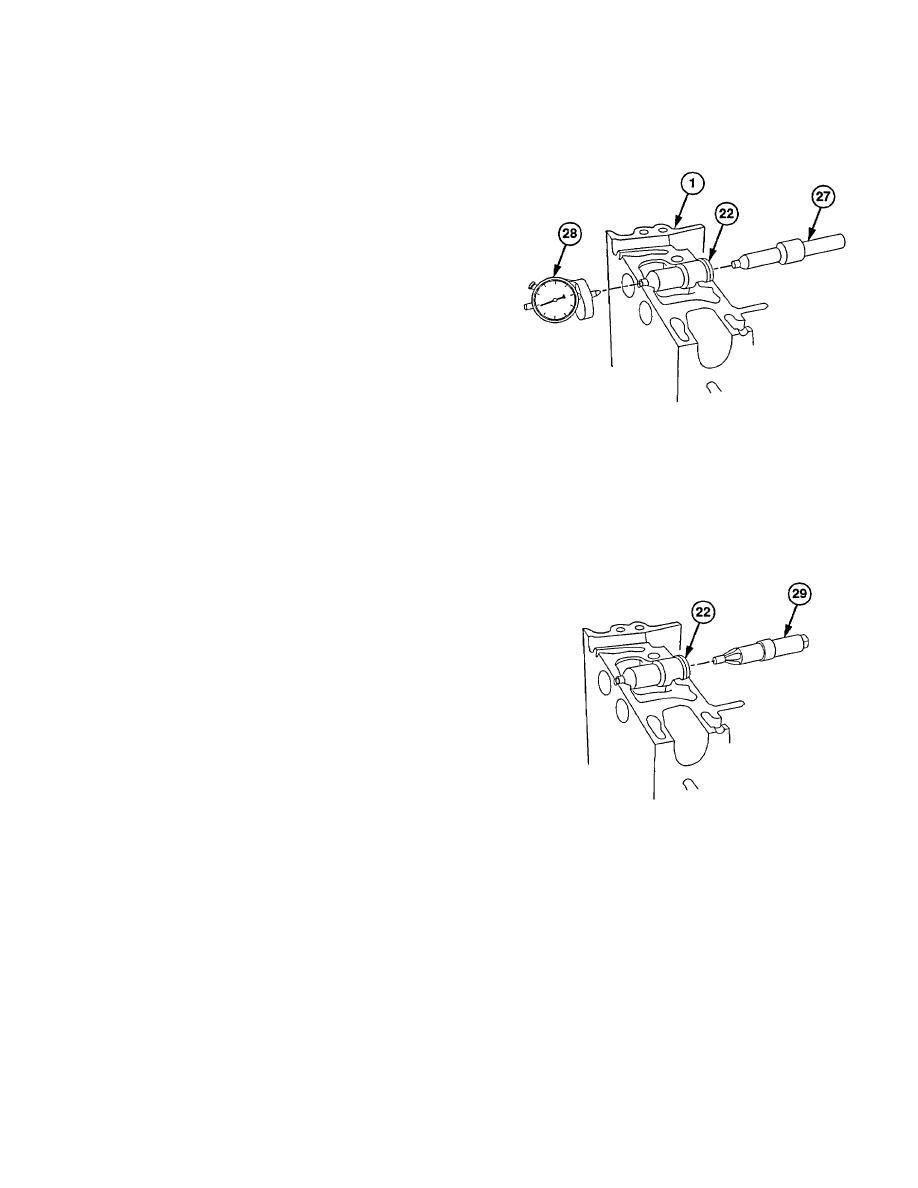

(45) Install injector gage (27) in injector tube (22).

(46) Zero sled gage dial indicator (28) on finished

surface of cylinder head (1).

NOTE

Tip of Injector gage must be flush

with or up to 0.014 in. (0.356 mm)

above or below finished surface of

cylinder head.

If injector gage is more than 0.014

in. above cylinder head surface,

replace injector tube.

If injector gage is more than 0.014

in. below cylinder head surface,

ream injector tube with nut reamer.

Refer to step (48).

(47) Hold Injector gage (27) in injector tube (22) and

move sled gage dial Indicator (28) onto tip of

injector gage (27). Note dial indicator reading

and determine difference from zero reading.

Remove sled gage dial indicator (28) and

injector gage (27).

NOTE

Do step (48) only if nut reaming is

required.

Remove a little metal at a time and

recheck measurement when using

nut reamer.

Always clean out

injector tube before taking a

reading.

(48) Remove excess stock from injector tube (22)

using nut reamer (29).

19-53

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |