|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

19-7. CYLINDER HEAD REPAIR (CONT)

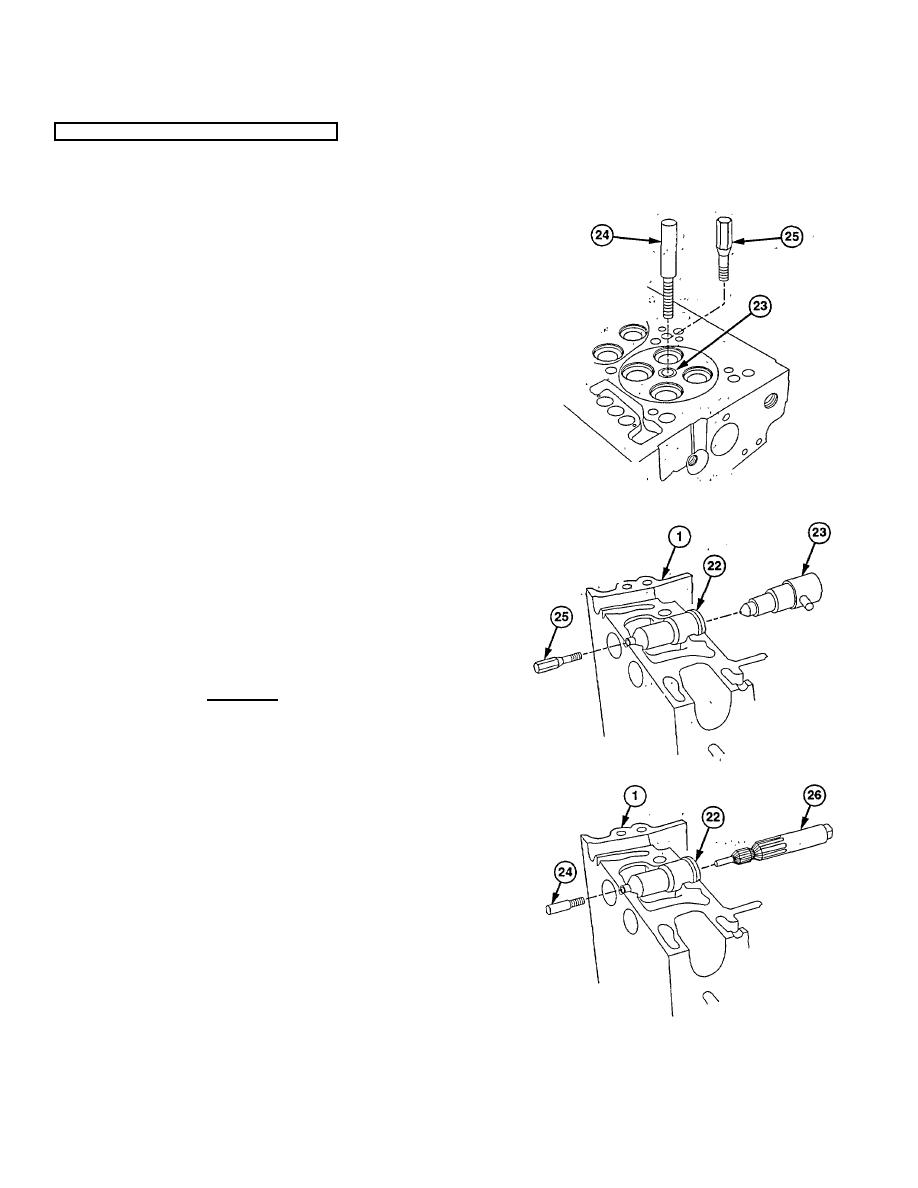

(34)

Remove pilot (24) and install upsetting die (25)

in injector tube Installer (23).

(35) Tighten upsetting die (25) to 30 lb-ft (41 Nm) to

flare lower end of injector tube (22).

(36) Remove injector tube installer (23) and upsetting

die (25).

NOTE

Reamer must be turned in clockwise

direction only when inserting and

withdrawing reamer. Movement in

opposite direction will dull cutting

edges.

(37) Place few drops of lubricating oil on cutting edge

of reamer (26) and carefully insert in injector

tube (22).

CAUTION

Ensure all metal chips and shavings

are removed prior to each reaming

operation. Failure to comply may

result in damage to equipment.

(38) Slowly turn reamer (26) clockwise, withdrawing

frequently to remove chips. Continue cutting

until shoulder of cutting edge on reamer (26)

contacts injector tube (22).

WARNING

Compressed

air

for

cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding and personal protective

equipment (goggles/shield, gloves,

etc.).

(39)

Clean out all metal chips with compressed air.

(40)

Install pilot (24) in reamer (26).

(41)

Place few drops of cutting oil on pilot (24).

(42)

Turn reamer (26) until lower end of injector tube

(22) is flush with or up to 0.005 in. (0.127 mm)

below finished surface on bottom of cylinder

head (1).

(43) Clean out all metal chips with compressed air.

(44) Remove reamer (26) and pilot (24).

19-52

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |