|

| |

TM 9-2320-360-34-1

1-17. AIR SYSTEM

The air system operates the service and parking brakes, rear suspension system, and the Central Tire Inflation System

(CTIS). Air also enables operation of the transfer case and interaxle lockups, winch tensioners and kickouts, windshield

washer, and horns.

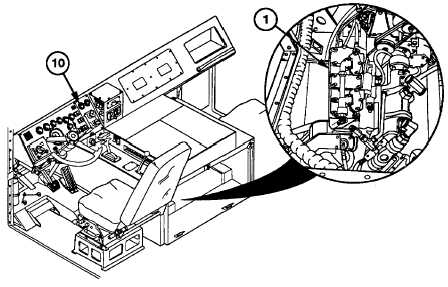

The air system on the HET Tractor consists of an engine-driven air compressor (1), a purge tank (2), and five air

reservoirs (3 thru 7). Reservoir (3) supplies air to reservoirs (4 thru 7). Three reservoirs (5 thru 7) are interconnected and

separated from reservoir (4) with check valves. Air from reservoir (4) is supplied to service brakes on all four axles and

parking brakes on the rear tridem axles, transfer case and interaxle lockups, winch tensioners and kickouts, windshield

washer, and horns. The service brakes are actuated by relay valves which are controlled by the operator pressing the

brake treadle in the cab. The parking brakes are also actuated by relay valves which are controlled by hand controls. In

the event of the loss of system air pressure, the spring brake valve will modulate the parking brakes so the HET Tractor

can be stopped safely. Reservoirs (5 thru 7) supply air to operate the CTIS, service and parking brakes on rear tridem

axles, and rear suspension system. Air is drawn from the engine air intake and routed to the air compressor (1) where it

is pressurized. Pressurized air flows from the air compressor (1) through an aftercooler (7.1), a coalescing filter (7.2), and

air dryers (8 and 9) where the air is cooled and moisture/oil is removed. Air from the dryers goes to the purge reservoir

(2) and air reservoir (3).

System protection elements include an air cleaner restriction sensor that determines whether air flow through the air

cleaner is impeded and also transmits a signal to a dash-mounted gage.

In the cab, air pressure in reservoir (4) is indicated by the green needle on the AIR PRESS gage (10). The red needle on

the gage (10) indicates air pressure in reservoirs (5 thru 7). If air pressure falls below 60 psi (414 kPa) in any of the

reservoirs, warning alarm will sound and LOW AIR indicator will light.

The rear suspension system contains a pair of suspension air bags on each rear axle that automatically inflates or

deflates according to load. Air to the air bags is regulated by a height control valve.

Purging the air in the air dryers and aftercooler is automatically done when 125 psi (862 kPa) system pressure is reached

at the compressor. The compressor cycle is stopped and air from purge tank clears accumulated water through a valve

on the bottom of the air dryer.

Air to the transfer case enables engagement of four-wheel drive in high or low gear range. An interaxle lockup pilot valve

also prevents the axles from locking up in high range.

1-8 Change 1

|