|

| |

TM 9-2320-356-BD

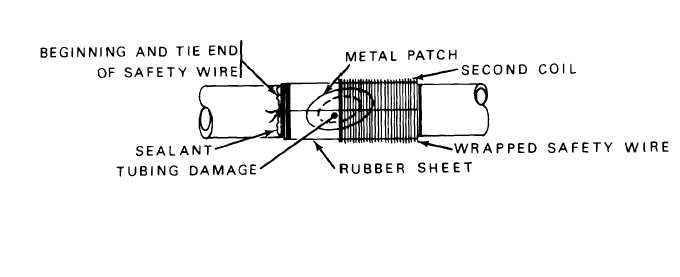

Option 4:

Patch Large Metal Lines.

1.

Smooth damaged area.

2.

Clean dirt and oil from damaged area.

3.

Cut a patch from thin sheet metal or

4.

Coat the metal patch and tubing with

5.

Cut a patch from rubber or other fuel

nonhardening sealer, if available.

6.

Wrap over metal patch.

an aluminum can.

sealant and place over damaged area.

-resistant material and coat with

7.

Wrap rubber patch with wire to equalize the pressure over the repair.

8.

Record the BDAR action taken.

When the mission is completed, as soon as

practicable, repair using standard maintenance procedures.

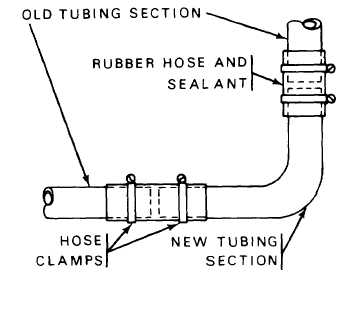

Option 5:

Repair Damaged Bends.

1.

Cut a bend from an old hydraulic

line, mirror arm, or similar item.

2.

Remove the damaged bend from the

l i n e.

3.

Clean the cut tubing ends.

4.

Apply sealant to tubing ends.

5.

Use two 2-inch sections of rubber

hose and install the replacement bend.

6.

Clamp with hose clamps or tightly

twisted wire.

6-12

|