|

| |

TM 9-2320-356-BD

Option 2:

Metal Tubing Cracked.

1.

Clean dirt and grease from around the crack.

2.

Coat the crack with sealant.

3.

Wrap tubing with a sheet of fuel-resistant material.

4.

Clamp the sheet directly over the crack.

5.

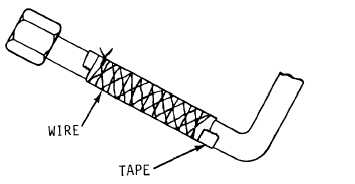

If clamps are not available,

6.

Wrap wire around the tape as

reinforcement.

wrap the tubing with tape.

7.

Wrap an additional coating of tape over the wire.

8.

Record the BDAR

practicable, repair

Option 3: Holes in

1.

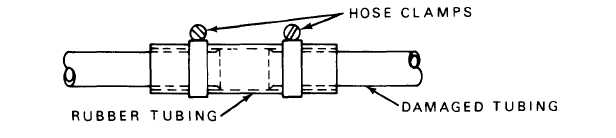

Cut out damaged

2.

Clean both ends

3.

4.

5.

6.

action taken.

When the mission is completed, as soon as

using standard maintenance procedures.

Metal Tubing.

portion of metal tubing.

of tubing.

Cut a piece of rubber hose 2 inches longer than the section removed.

Apply sealant to both ends of tubing.

Insert the tubing ends 1 inch into the hose.

Secure with loose clamps or tightly twisted wire.

7.

If the hose is too large, the tubing can be flared or sleeved to fit.

8.

Record the BDAR action taken.

When the mission is completed, as soon as

practicable, repair using standard maintenance procedures.

6-11

|