|

|||

|

|

|||

|

Page Title:

Air Compressor - Remove and Install |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

4. Place the electric starting motor in the flywheel

housing. Install three bolts (1).

5. Connect all of the electrical wires to the electric

starting motor by using the index marks.

i01748218

Air Compressor - Remove and

Install

SMCS Code: 1803-010

Removal Procedure

Table 53

Required Tools

Tool

Part Number

Part Description

Qty

138-7573

1

A

Link Bracket

g00609682

Illustration 283

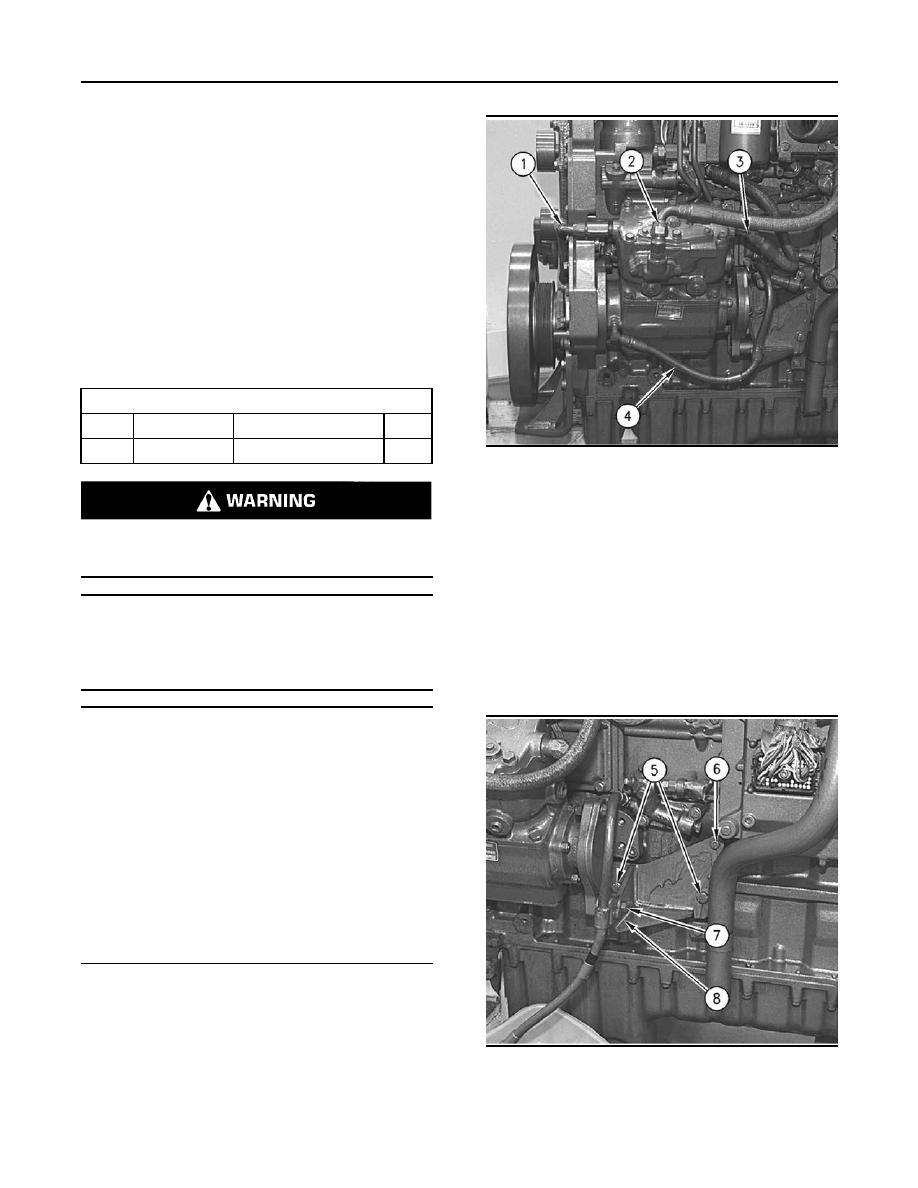

2. Disconnect water hose (1) and water hose (3)

from the air compressor.

Do not disconnect the air lines until the air pres-

3. Disconnect air hose (2) and oil hose (4) from the

sure in the system is at zero. If hose is disconnect-

air compressor.

ed under pressure it can cause personal injury.

4. Install Tooling (A) and a proper lifting device

to the air compressor. The weight of the air

NOTICE

compressor is approximately 23 kg (51 lb).

Keep all parts clean from contaminants.

5. Remove the mounting bracket for a Midland

Contaminants may cause rapid wear and shortened

EL-740 air compressor by using the following

component life.

procedure:

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar

Tools and Shop Products Guide" for tools and supplies

suitable to collect and contain fluids on Caterpillar

products.

Dispose of all fluids according to local regulations and

mandates.

1. Remove the air pressure from the air tank and

drain the coolant from the cooling system.

g00609684

Illustration 284

a. Remove bolt (8) and the clip for the oil hose

from the bracket for the air compressor.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |