|

|||

|

|

|||

|

Page Title:

Electric Starting Motor - Remove and Install |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

g00609523

g00894904

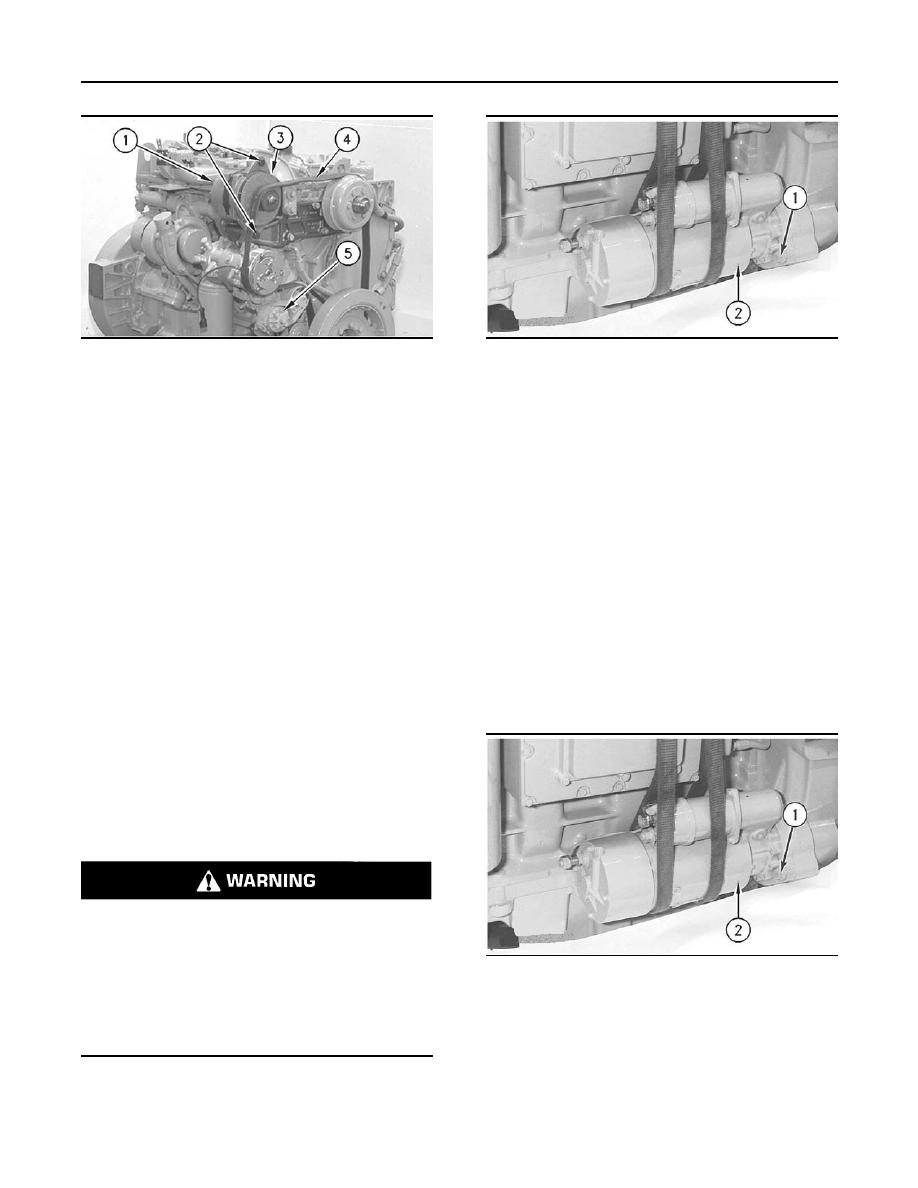

Illustration 280

Illustration 281

Typical example

Typical example

1. Place an index mark on all of the electrical wires

Install bolts (2).

that are connected to the electric starting motor.

Disconnect the electrical wires from the electric

2. Use Tooling (A) to install drive belt (4) on the

starting motor (2).

drive pulley of the alternator.

2. Fasten a suitable lifting device to the electric

Note: Adjust the tension on the drive belt if the

starting motor.

engine is not equipped with a belt tensioner. Refer

to the Operation and Maintenance Manual for the

3. Remove three bolts (1).

correct adjusting procedure.

4. Remove the electric starting motor and the

gasket from the flywheel housing. The weight of

marks to correctly connect the wires. Tighten the

the electric starting motor is approximately 29 kg

mounting bolt for the ground wire to a torque

(65 lb).

of 6.2 0.6 Nm (54 5 lb in). Tighten the

mounting bolt for the battery wire to a torque of

Installation Procedure

11.3 2.3 Nm (100 20 lb in).

1. Inspect the condition of the gasket. Replace the

gasket, if necessary.

i01748192

Electric Starting Motor -

Remove and Install

SMCS Code: 1453-010

Removal Procedure

Personal injury can result from failure to discon-

nect the battery.

First, disconnect the negative battery cable. Then,

g00894904

Illustration 282

disconnect the positive battery cable.

Typical example

A positive power lead can cause sparks if the bat-

2. Install the gasket on the electric starting motor

tery is not disconnected. Sparks can possibly re-

(2).

sult in battery explosion or fire.

3. Fasten a suitable lifting device to the electric

starting motor.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |