|

|||

|

|

|||

|

Page Title:

Crankshaft Main Bearings - Remove |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

Start By:

a. Remove the engine oil pump. Refer to

Disassembly and Assembly, "Engine Oil Pump -

Remove".

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

g00678202

Illustration 226

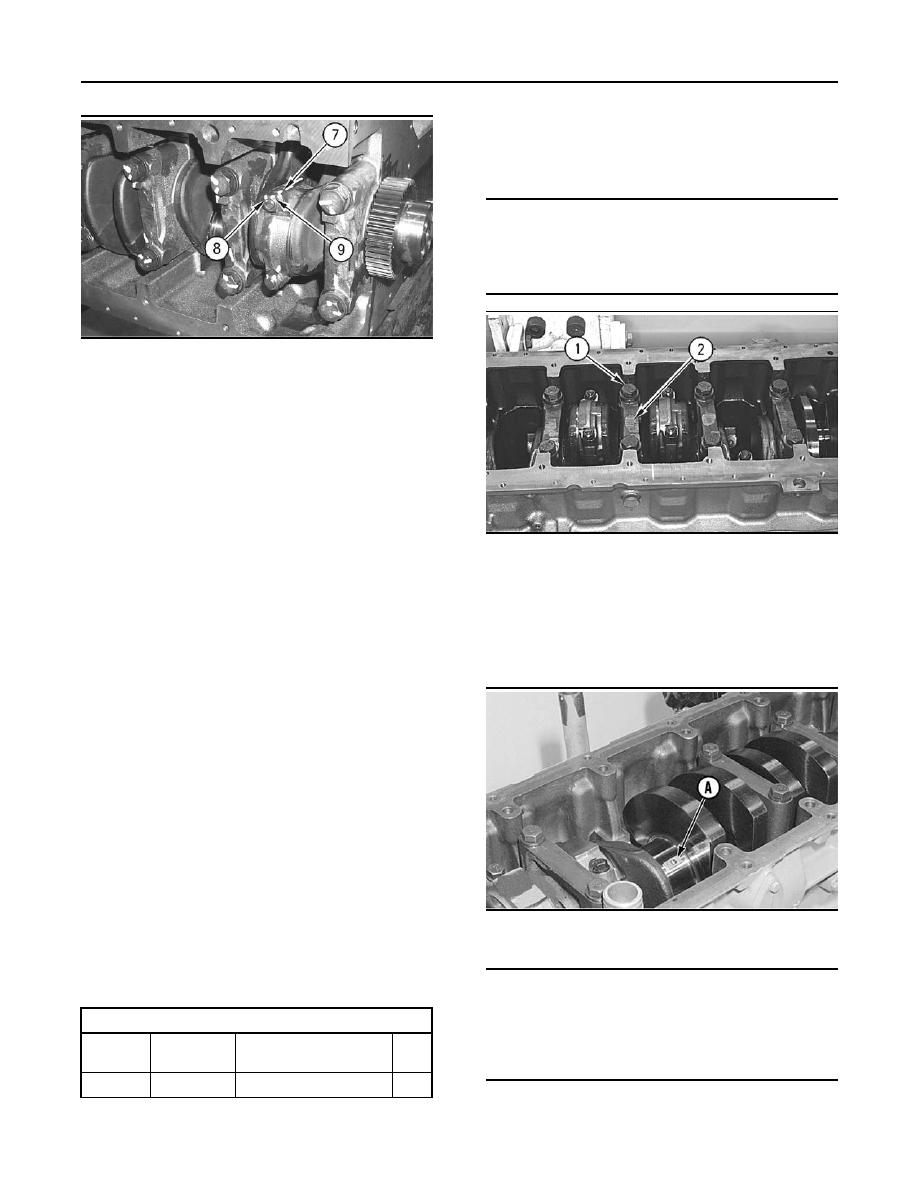

13. Place index mark (7) on the connecting rod.

Place index mark (9) on connecting rod cap

nut (1). Index marks (7) and (9) mark the initial

position of the nut. Place index mark (8) on

connecting rod cap nut (1). Index mark (8)

should be 60 5 degrees counterclockwise

from index mark (9). Tighten each nut (1) for

an additional 60 5 degrees (1/6 turn). Index

mark (8) should be lined up with index mark (7).

Repeat the procedure for the other connecting

g00610152

rod cap nut.

Illustration 227

1. Remove bolts (1) that hold crankshaft main

14. Repeat Steps 1 through 13 for the remaining

bearing cap (2). Remove crankshaft main

pistons and connecting rods.

bearing cap (2).

End By:

2. Remove the lower half of the crankshaft main

bearing from crankshaft main bearing cap (2).

a. Install the piston cooling jets. Refer to

Disassembly and Assembly, "Piston Cooling Jets

- Remove and Install".

b. Install the engine oil pump. Refer to Disassembly

and Assembly, "Engine Oil Pump - Install".

c. Install the cylinder head. Refer to Disassembly

and Assembly, "Cylinder Head - Install".

i01747897

Crankshaft Main Bearings -

Remove

g00516920

SMCS Code: 1203-011

Illustration 228

Typical example

Removal Procedure

NOTICE

Table 42

If the crankshaft is turned in the wrong direction, the

tab of the crankshaft main bearing will be pushed be-

Required Tools

tween the crankshaft and the cylinder block. this can

Part

cause damage to either or both the crankshaft and the

Tool

Part Description

Qty

Number

cylinder block.

1

2P-5518

A

Bearing Tool

3. Use the following steps in order to remove the

upper half of crankshaft main bearings:

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |