|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

9. Test the actuation pressure. Increase the

actuation pressure to the maximum pressure

(approximately 3300 psi).

level. Supply the proper amount of oil to the

End By:

a. Install the valve mechanism cover. Refer to

Disassembly and Assembly, "Valve Mechanism

Cover - Remove and Install".

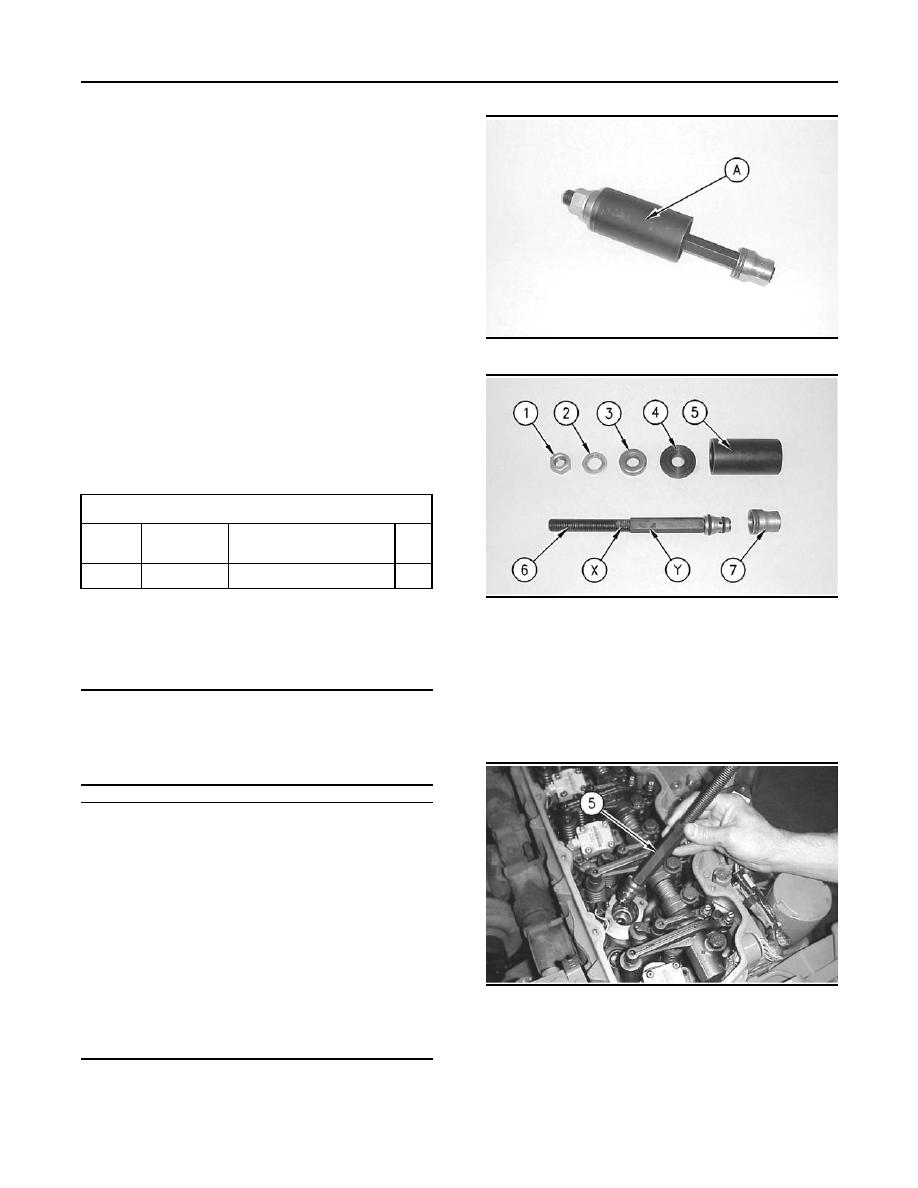

g00616609

Illustration 34

i01745226

Unit Injector Sleeve - Remove

SMCS Code: 1713-011

Removal Procedure

Table 6

Required Tools

Part

Tool

Part Description

Qty

Number

151-4832

A

1

Injector Sleeve Tool

g00616610

Illustration 35

Start By:

(1) Nut

(2) Washer

a. Remove the unit injectors. Refer to Disassembly

(3) Bearing

and Assembly, "Unit Injector - Remove".

(4) Washer

(5) Sleeve

(6) Threaded rod assembly

NOTICE

(7) Unit injector sleeve

Keep all parts clean from contaminants.

(X) Threaded part of the rod assembly

(Y) Expandable part of the rod assembly

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar

Tools and Shop Products Guide" for tools and supplies

suitable to collect and contain fluids on Caterpillar

g00616556

products.

Illustration 36

Dispose of all fluids according to local regulations and

mandates.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |