|

|||

|

|

|||

|

Page Title:

Check the Fuel System for Leaks |

|

||

| ||||||||||

|

|

15

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

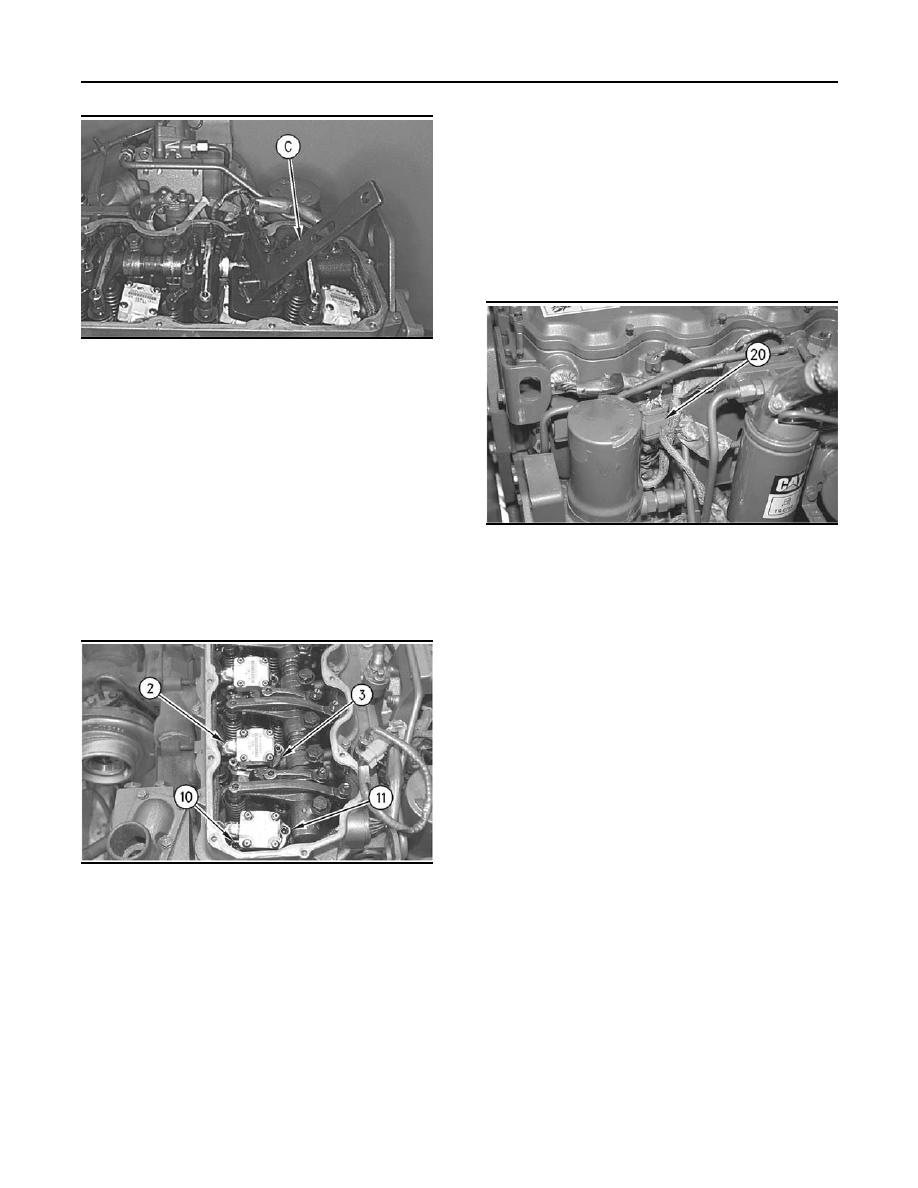

7. Insert the harness connectors (2) back into the

injectors' solenoids. Ensure that the clips are

snapped back into the proper position.

8. Check the system for leaks by using the following

procedure.

Check the Fuel System for Leaks

1. Visually inspect the components of the injector

for oil leaks around the outside diameter.

g00312124

Illustration 31

(C) 152-1057 Fuel Injector Installer

5. Carefully install the injector into the injector bore.

If access permits you to seat the injector, push

the injector straight down on top of the injector's

solenoid by hand until the injector is firmly

seated in the injector bore. Pushing hard enough

to compress the injector's seals may be difficult.

If the injector can not be seated by hand, use a

152-1057 Fuel Injector Installer (C).

g00778891

Illustration 33

Note: Do NOT pry on the top of the injector with

another tool. Do NOT strike the injector with a

2. Disconnect the injector wiring harness with

hammer. Damage to the injector will result. Damage

the 12-pin connector (20). The harness is

to the injector that is due to improper installation is

located between the hydraulic pump and the

not a warrantable failure.

cylinder head. Disconnect the Injection Actuation

Pressure Sensor's connector. This will cause the

oil pressure to raise to about 2500 psi.

3. Crank the engine in order to allow the actuation

pressure to rise. Cranking the engine also purges

the air from the system.

4. Visually check for oil leaks in the area that is

between the outside diameter of the injector and

the cylinder block.

Note: A small amount of seepage from the injector's

vent hole during cranking is normal. A large steady

flow from one injector that is greater than the flow

from the other injectors may indicate a problem with

g00778888

Illustration 32

that injector.

(2) Wiring Harness Connection

(3) Clamp

5. If no leaks are found, connect the injector wiring

(10) Shoulder Bolt

harness (20) and the Injection Actuation Pressure

(11) Socket Head Bolt

Sensor.

Note: Do not use the shoulder bolt and the socket

6. Start the engine.

head bolt in order to seat the injector. If a side load

is placed on the bolts, the bolts may fail.

7. Check for oil leaks while the engine is running

at idle.

6. After the injector is seated, position the clamp

(2) and tighten the Shoulder Bolt (10) to a torque

8. If no leaks are found, install the ET or other

of 6 Nm (50 lb in). Then tighten the Socket Head

electronic service.

Bolt (11) to a torque of 12 Nm (9 lb ft).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |