|

|||

|

|

|||

|

Page Title:

Test Step 2. Check the Installation of the Sensors and the Bracket |

|

||

| ||||||||||

|

|

256

TM 9-2320-312-24-2

Troubleshooting Section

Note: The bracket cannot be replaced separately.

Note: If the diagnostic code is logged but not

active, run the engine until the engine is at normal

C. Ensure that one O-ring has been installed on

operating temperature. The problem may only

the sensor, and ensure that the O-ring is free of

occur when the engine is at the normal operating

damage.

temperature. If the engine will not start, monitor the

engine rpm from the electronic service tool while

Note: If the flange of the sensor is bent or if an

the engine is being cranked. The electronic service

obstruction is preventing the sensor from reading a

tool may need to be powered from another battery

good pattern, the engine will not start.

while the engine is being cranked. This is done in

order to ensure that the electronic service tool does

not reset.

Results:

OK The sensors and the bracket are properly

Expected Result:

installed. Proceed to Test Step 3.

One or more of the diagnostic codes that are listed

Not OK

above are logged or active.

Note: If you have been referred here from

Repair: Perform the following procedure in order

Troubleshooting, "Troubleshooting without a

to properly install the sensors and the bracket:

Diagnostic Code" for the following reason, select

"No Engine rpm":

1. Loosen the bolt that holds the sensor mounting

bracket to the engine.

The engine rpm was not indicated on the

2. Seat the sensor and tighten the bolt.

electronic service tool.

If the sensor will not seat, repair the sensor or

Results:

replace the sensor, as required.

OK There is an active diagnostic code or a

Note: The sensor must not be removed from the

logged diagnostic code. Proceed to Test Step 3.

bracket.

Not OK If none of the codes that are listed are

3. Ensure that the sensor is properly oriented

active diagnostic codes or logged diagnostic

and that the harness is secured in the proper

codes and the engine is not running properly,

location.

refer to the appropriate symptoms in the service

manual. STOP.

4. Verify that the repair eliminates the problem.

No Engine rpm Engine rpm is not indicated on

STOP.

the electronic service tool. Proceed to Test Step 2.

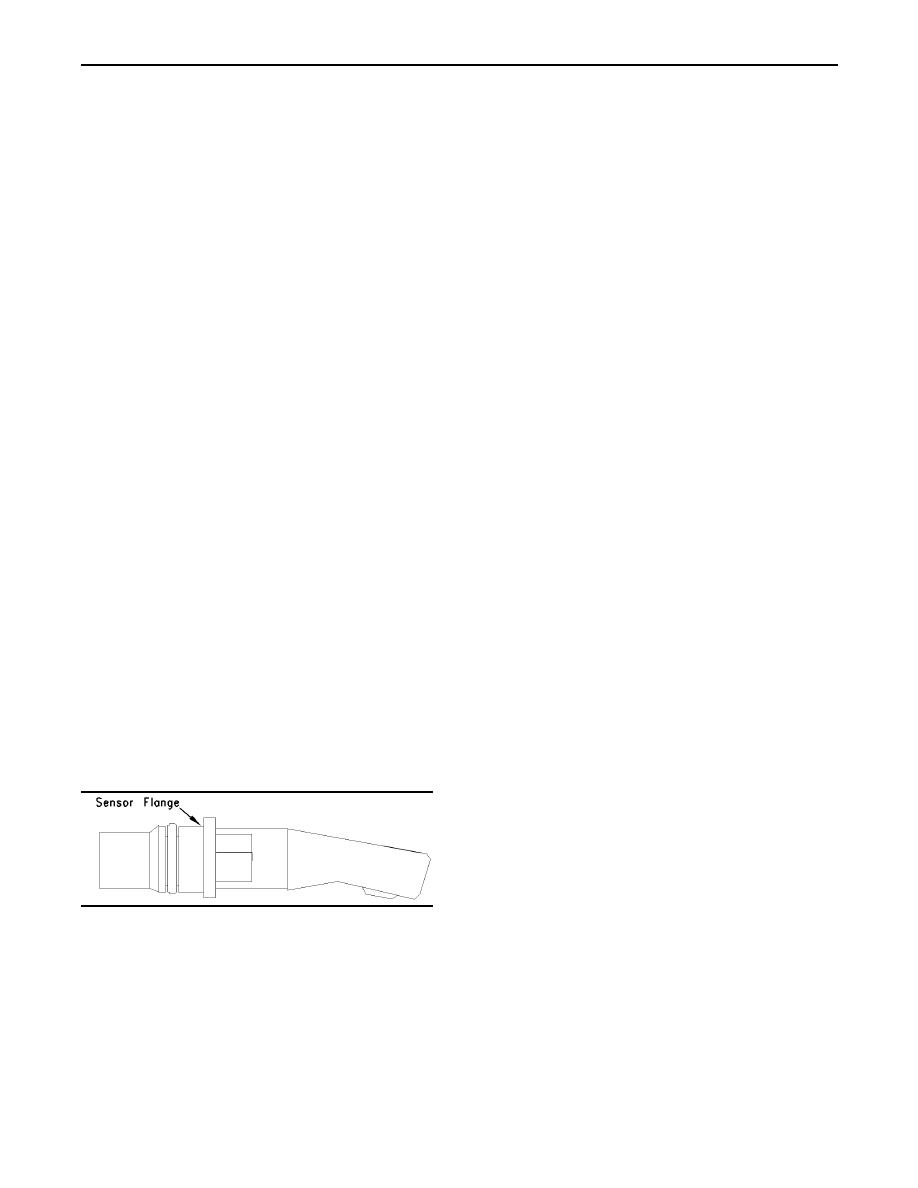

Test Step 2. Check the Installation of the

Sensors and the Bracket

g00767308

Illustration 92

Flange of the sensor and mounting bracket

A. The flange of the sensor should be flush against

the engine in order to ensure proper operation.

B. Inspect the bracket in order to ensure that the

installation allows the flange of the sensor to be

flush against the engine.

Verify that the bracket is not bent.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |