|

|||

|

|

|||

|

Page Title:

Snapshot Information that Is Triggered Externally |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Troubleshooting Section

Replacement of electronic components should

not be based on the snapshot data alone. When

the snapshot information is triggered externally, the

snapshot information is stored in frames during

every 0.24 seconds. When the snapshot information

is triggered by a diagnostic code , the snapshot

information is stored in frames during every 0.48

seconds. Frequently, the parameters are changing

at a rate that is different from 0.24 seconds. If

too much emphasis is put on this information, the

result could be a misdiagnosed problem. Also

when snapshot information that is triggered by a

diagnostic code is being viewed, the ECM sets

a sensor value with an active diagnostic code to

a default value when the code is active. This is

g00627693

Illustration 13

the reason that the sensor value suddenly jumps

to a specific value at the trigger point and the

(1) OFF position

(2) SET position

sensor value remains there for the rest of the

(3) RESUME position

snapshot frames. DO NOT attempt to interpret

the information and DO NOT attempt to analyze

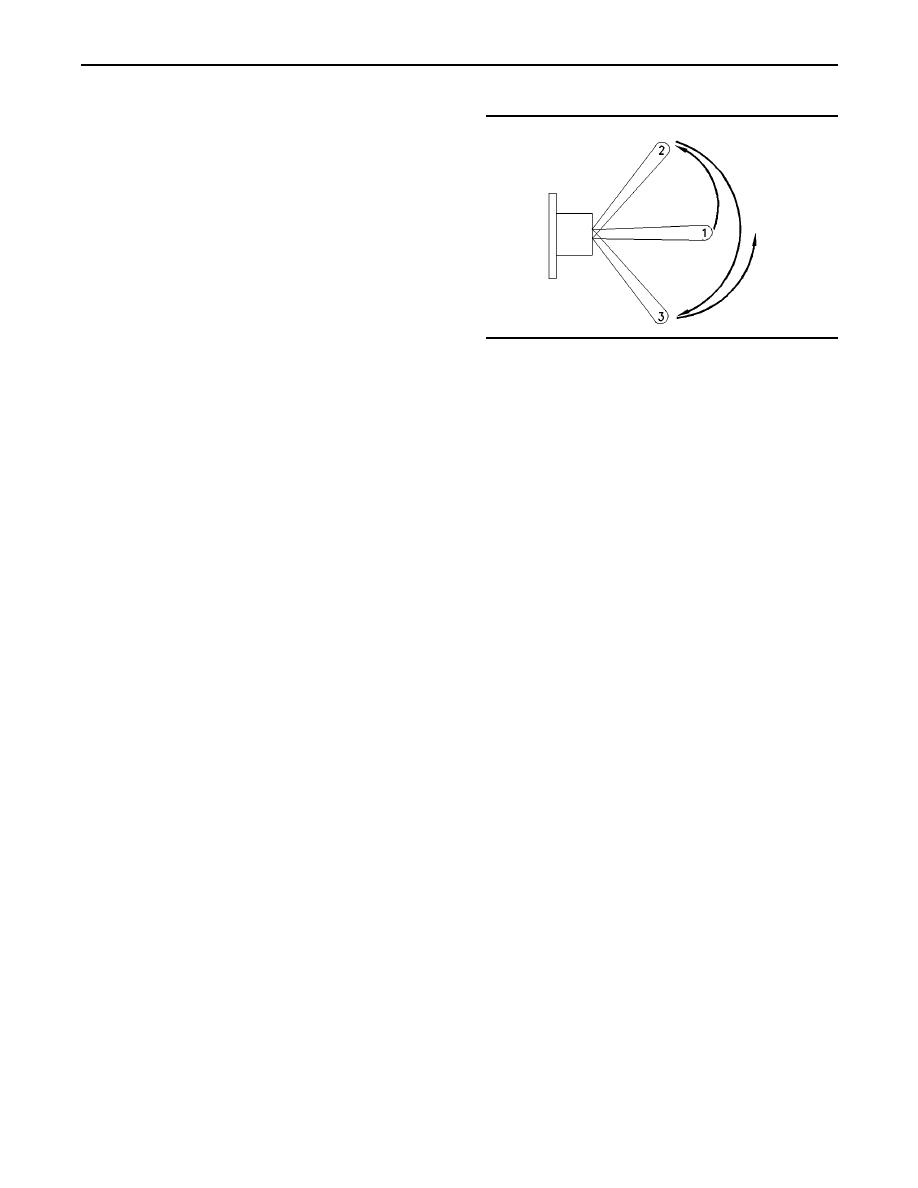

1. Toggle the switch quickly from the OFF position

the reason that the engine is operating from this

(1) to the SET position (2).

historical information. Incorrect diagnoses will occur

by looking at this information under a microscope.

2. Toggle the switch quickly from the SET position

Incorrect diagnoses will occur because some of

(2) to the RESUME position (3).

the parameters will not be set to the values that

are expected. Even though the parameters are not

3. Toggle the switch quickly from the RESUME

related to the problem that is under investigation,

position (3) back to the OFF position (1).

the parameters can lead to incorrect diagnoses.

Note: The switch must be toggled within a one

Snapshot Information that is

second time period in order to take a snapshot of

the engine parameters. The procedure can also be

Triggered by a Diagnostic Code

performed in the reverse order.

When a diagnostic code occurs the ECM records

The snapshot can be triggered from the Snapshot

many of the status parameters that are available on

Recorder Tool in ET. Refer to the instructions on the

the Caterpillar ET. The ECM records this information

screen or the system's documentation for help.

for approximately 9 seconds before the code

occurs, and approximately 4 seconds after the

Quick Stop Snapshot

code.

A snapshot can also be stored for a quick stop

Snapshot Information that Is

event if the customer parameter is programmed.

Triggered Externally

The ECM stores the number of occurrences of the

Quick Stop Event and a snapshot of the latest

A snapshot can be triggered externally by using

occurrence.

either the cruise control set/resume switch, or

Caterpillar Electronic Technician (ET). Use the

One data record is kept for the most recent quick

following procedure in order to trigger the snapshot

stop event. The previous record is replaced by the

by using the cruise control set/resume switch:

most recent record.

Each quick stop record contains 60 frames of

information. Frame 45 is the quick stop event. The

record contains 44 frames before the quick stop

event and 15 frames following the quick stop event.

Each frame is separated by 1.0 second. Each frame

of the quick stop record stores the following data:

Engine rpm

Throttle position

Clutch switch

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |