|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Testing and Adjusting Section

If you use any other method except the method that

is given here, always remember that the bearing

clearance must be removed in order to receive the

correct measurements.

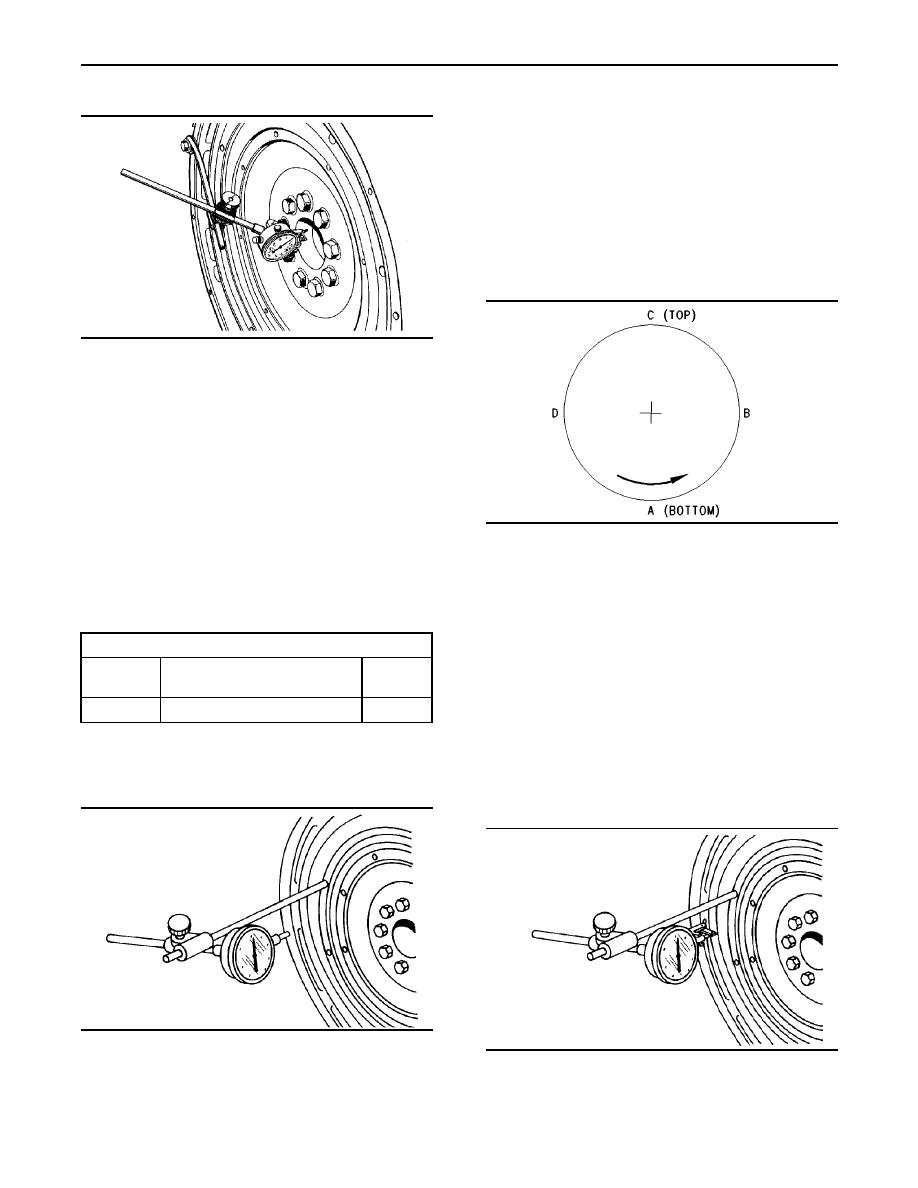

1. Fasten a dial indicator to the flywheel so the anvil

of the dial indicator will contact the face of the

flywheel housing.

2. Put a force on the crankshaft toward the rear

before the dial indicator is read at each point.

g00286058

Illustration 81

Flywheel clutch pilot bearing bore

5. To find the runout (eccentricity) of the pilot

bearing bore, use the preceding procedure.

6. The runout (eccentricity) of the bore for the pilot

bearing in the flywheel must not exceed 0.13 mm

(0.005 inch).

i01340595

g00285932

Illustration 83

Flywheel Housing - Inspect

Checking face runout of the flywheel housing

3. Turn the flywheel while the dial indicator is set at

SMCS Code: 1157-040

0.0 mm (0.00 inch) at location (A). Read the dial

indicator at locations (B), (C) and (D).

Table 26

Tools Needed

4. The difference between the lower measurements

Part

and the higher measurements that are performed

Part Name

Quantity

Number

at all four points must not be more than 0.30 mm

(0.012 inch), which is the maximum permissible

8T-5096

1

Dial Indicator

face runout (axial eccentricity) of the flywheel

housing.

Face Runout (Axial Eccentricity) of

Bore Runout (Radial Eccentricity)

the Flywheel Housing

of the Flywheel Housing

g00285931

Illustration 82

g00285934

8T-5096 Dial Indicator

Illustration 84

8T-5096 Dial Indicator

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |