|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Testing and Adjusting Section

Bore Runout (radial eccentricity) of

i01284996

the Flywheel

Flywheel - Inspect

SMCS Code: 1156-040

Table 25

Tools Needed

Part

Part Name

Quantity

Number

8T-5096

1

Dial Indicator

Face Runout (axial eccentricity) of

the Flywheel

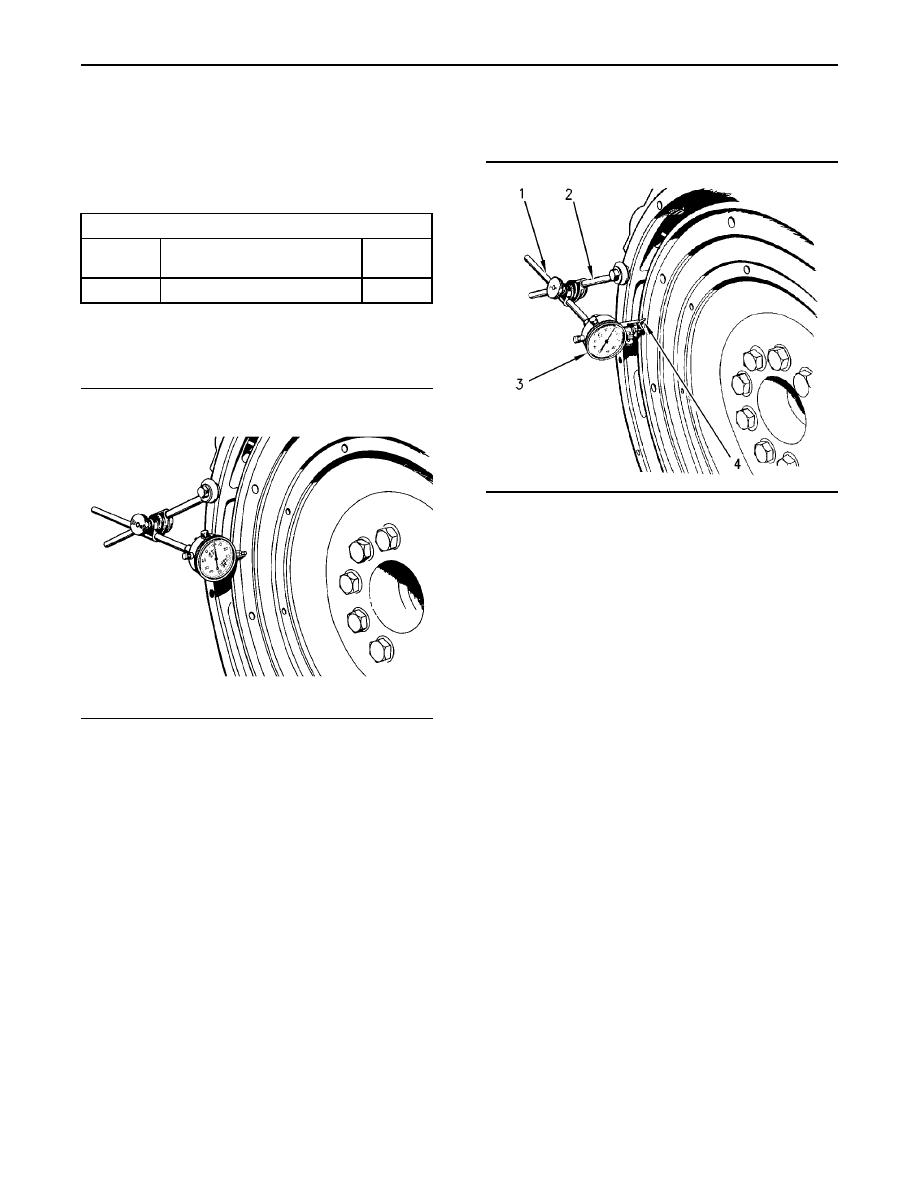

g00286054

Illustration 80

Checking bore runout of the flywheel

(1)

Holding Rod

7H-1945

(2)

Holding Rod

7H-1645

(3)

Dial Indicator

7H-1942

(4)

Universal Attachment

7H-1940

1. Install 7H-1942 Dial Indicator (3). Make an

adjustment of 7H-1940 Universal Attachment

(4) so the dial indicator makes contact on the

flywheel.

2. Set the dial indicator to read 0.0 mm (0.00 inch).

g00286049

3. Turn the flywheel at intervals of 90 degrees and

Illustration 79

read the dial indicator.

Checking face runout of the flywheel

4. Take the measurements at all four points. The

1. Refer to Illustration 79 and install the dial

difference between the lower measurements and

indicator. Always put a force on the crankshaft

the higher measurements that are performed at

in the same direction before the dial indicator

all four points must not be more than 0.15 mm

is read. This will remove any crankshaft end

(0.006 inch), which is the maximum permissible

clearance.

face runout (radial eccentricity) of the flywheel.

2. Set the dial indicator to read 0.0 mm (0.00 inch).

3. Turn the flywheel at intervals of 90 degrees and

read the dial indicator.

4. Take the measurements at all four points. The

difference between the lower measurements and

the higher measurements that are performed at

all four points must not be more than 0.15 mm

(0.006 inch), which is the maximum permissible

face runout (axial eccentricity) of the flywheel.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |