|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Systems Operation Section

As the camshaft turns, each lobe moves a lifter

assembly. There are two lifter assemblies for each

cylinder. Each lifter assembly moves a pushrod.

Each pushrod moves a valve (exhaust) or a set of

valves (inlet). The camshaft must be in time with the

crankshaft. The relation of the camshaft lobes to

the crankshaft position causes the valves in each

cylinder to operate at the correct time.

i01854525

Electrical System

SMCS Code: 1400; 1550; 1900

Grounding Practices

Proper grounding for the vehicle electrical system

and the engine electrical systems is necessary for

proper vehicle performance and reliability. Improper

grounding will result in unreliable electrical circuit

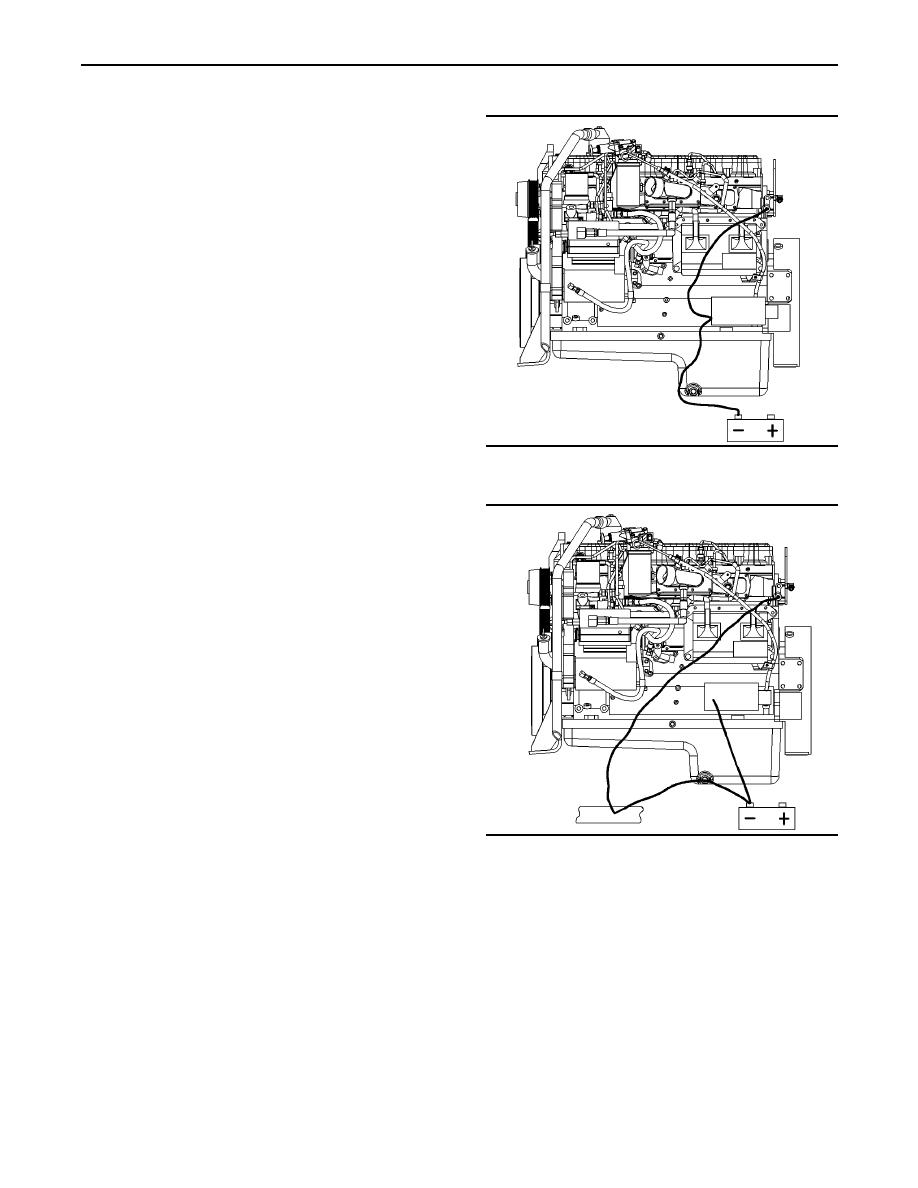

g00769833

Illustration 40

paths and uncontrolled electrical circuit paths.

Grounding Stud To Battery Ground ("-")

Uncontrolled engine electrical circuit paths can

result in damage to main bearings, crankshaft

bearing journal surfaces, and aluminum

components.

Uncontrolled electrical circuit paths can cause

electrical noise which may degrade the vehicle and

radio performance.

To ensure proper functioning of the vehicle and

engine electrical systems, an engine-to-frame

ground strap with a direct path to the battery must

be used. This may be provided by a starting motor

ground, by a frame to starting motor ground, or by

a direct frame to engine ground. An engine-to-frame

ground strap must be used in order to connect the

grounding stud of the engine to the frame of the

vehicle and to the negative battery post.

g00769834

Illustration 41

Alternate Grounding Stud To Battery Ground ("-")

The engine must have a wire ground to the battery.

Ground wires or ground straps should be combined

at ground studs that are only for ground use. The

engine grounds should be inspected after every

20125 km (12,500 miles) or every 250 hours. All of

the grounds should be tight and free of corrosion.

The engine alternator should be battery ground with

a wire size that is capable of managing the full

charging current of the alternator.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |