|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

56

TM 9-2320-312-24-2

Systems Operation Section

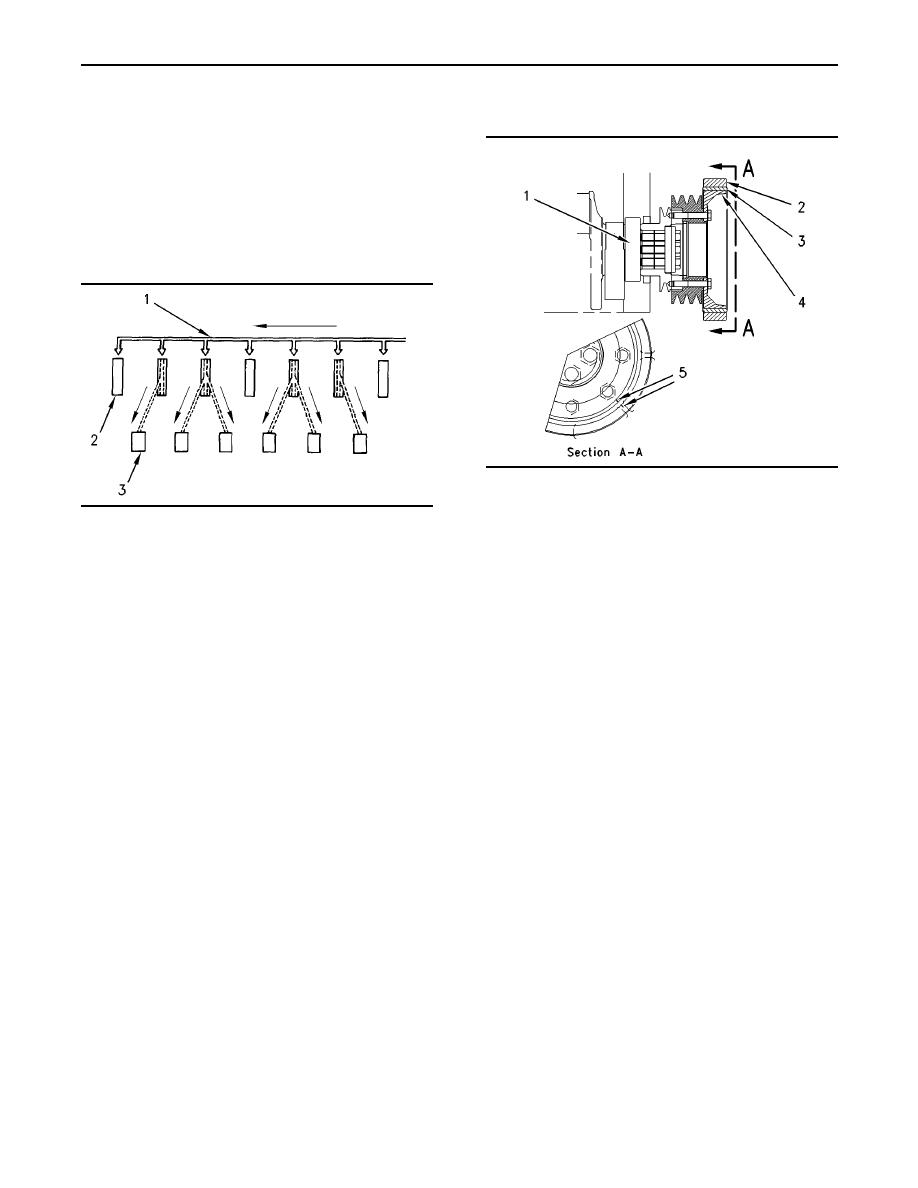

Rubber Vibration Damper

Refrigerant compressor

Hydrodynamic seals are used at both ends of the

crankshaft to control oil leakage. The hydrodynamic

grooves in the seal lip move lubrication oil back into

the crankcase as the crankshaft turns. The front

seal is located in the front housing. The rear seal is

installed in the flywheel housing.

g00293231

Illustration 39

Rubber vibration damper

g00293227

(1)

Crankshaft

Illustration 38

(2)

Ring

Schematic of oil passages in crankshaft

(3)

Rubber ring

(1) Oil gallery

(4)

Hub

(2) Main bearings

(5)

Alignment marks

(3) Connecting rod bearings

The rubber vibration damper is installed on the

Pressure oil is supplied to all main bearings through

front of crankshaft (1). The hub (4) and ring (2) are

drilled holes in the webs of the cylinder block.

isolated by a rubber ring (3). The rubber vibration

The oil then flows through drilled holes in the

damper has alignment marks (5) on the hub and

crankshaft in order to provide oil to the connecting

the ring. These marks give an indication of the

rod bearings. The crankshaft is held in place by

condition of the rubber vibration damper.

seven main bearings. A thrust bearing next to the

rear main bearing controls the end play of the

Camshaft

crankshaft.

The camshaft is located in the upper left side of the

Vibration Damper

cylinder block. The camshaft is driven by gears at

the front of the engine. Seven bearings support the

The force from combustion in the cylinders will

camshaft. A thrust plate is mounted between the

cause the crankshaft to twist. This is called torsional

camshaft drive gear and a shoulder of the camshaft

vibration. If the vibration is too great, the crankshaft

in order to control the end play of the camshaft.

will be damaged. The vibration damper limits the

torsional vibrations to an acceptable amount in

The camshaft is driven by an idler gear which

order to prevent damage to the crankshaft.

is driven by the crankshaft gear. The camshaft

rotates in the same direction as the crankshaft. The

crankshaft rotates in the counterclockwise direction

when the engine is viewed from the flywheel end

of the engine. There are timing marks on the

crankshaft gear, the idler gear, and the camshaft

gear in order to ensure the correct camshaft timing

to the crankshaft for proper valve operation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |