|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-312-24-2

Specifications Section

1. Tighten the clamps to a torque of 14 1.1 Nm

(125 10 lb in).

2. Tap lightly around the circumference of the

clamp.

3. Tighten the clamps again. Tighten the clamps to

a torque of 14 1.1 Nm (125 10 lb in).

Note: Put clean engine oil in the oil inlet of the

turbocharger after assembly or before installation.

This will provide lubrication during start-up and

during storage.

g00777400

Illustration 15

i01498928

Air Inlet Elbow

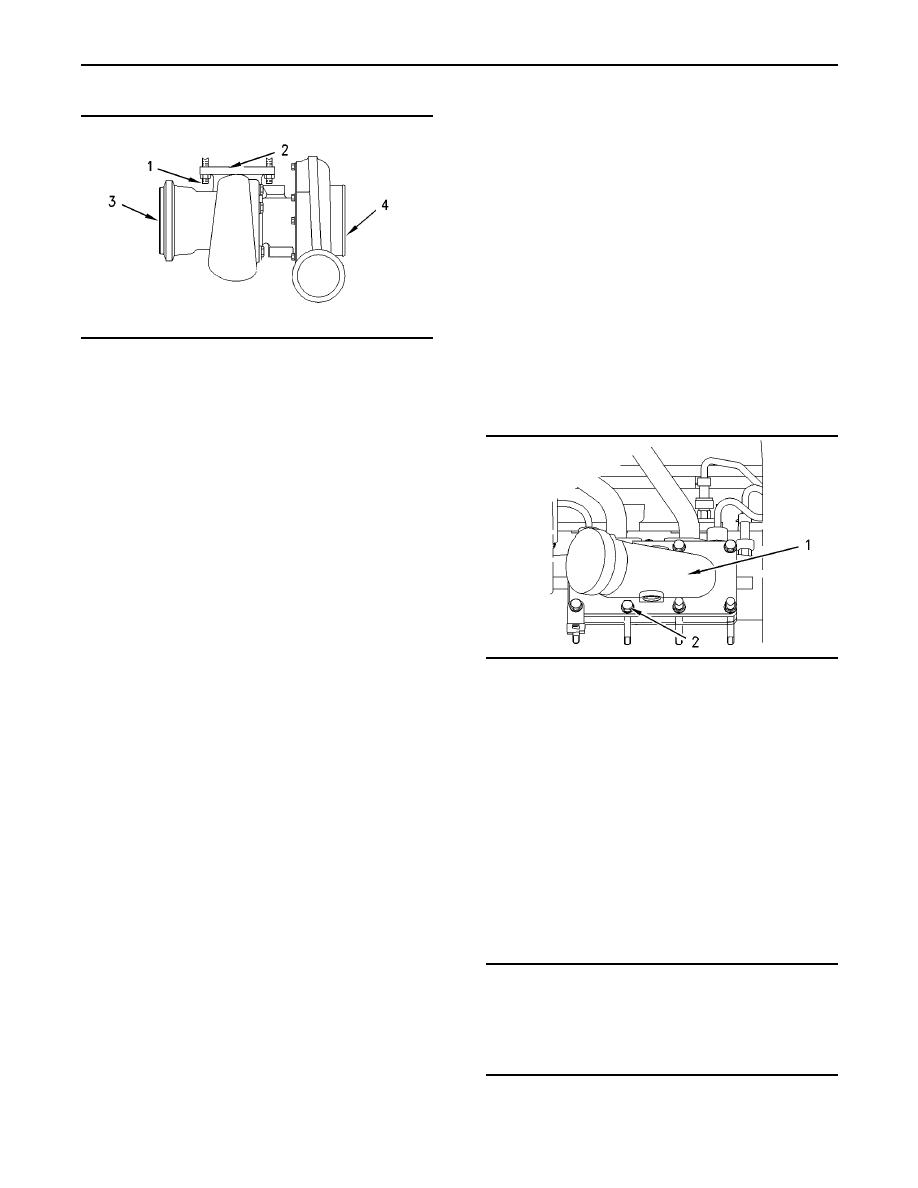

Typical example of turbocharger without a wastegate

(1) Stud

SMCS Code: 1071

Apply 5P-3931 Anti-Seize Compound to the studs.

The 136-0610 Turbocharger and the 136-0611

Turbocharger are secured to the exhaust manifold

with the 3E-8017 Locknut. Tighten the 3E-8017

Locknut to the following torque. ............. 54 5 Nm

(40 4 lb ft)

Note: The 3E-8017 Locknut has a special thread

form that is identifiable from a standard thread. This

thread form is called a Spiralock thread.

The 136-0612 Turbocharger and 136-0613

Turbocharger is secured to the exhaust manifold

with the 9X-6620 Locknut. Tighten the 9X-6620

g00777818

Illustration 16

Locknut to the following torque. ............. 70 5 Nm

(50 4 lb ft)

(1) Air Inlet Elbow

Note: The 9X-6620 Locknut is a locknut with a

Apply 1U-8846 Liquid Gasket to the face of

standard thread form.

the elbow and spread the sealant uniformly. The

elbow must be assembled and the elbow must be

(2) Exhaust inlet

tightened within ten minutes.

(3) Exhaust outlet

(2) Tighten the bolts to the following

torque. ........................ 28 7 Nm (21 5 lb ft)

(4) Air inlet

(5) Waste gate

i01675931

Exhaust Manifold

Opening pressure of the wastegate .... 148 3 kPa

(21.5 0.5 psi)

SMCS Code: 1059

End play for a new shaft .............. .102 0.025 mm

NOTICE

(.0040 .0010 inch)

Excessive use of sealant can cause damage to com-

ponents.

Maximum permissible end play for a worn

shaft ......................................... 0.20 mm (.008 inch)

To avoid component damage use only the amount of

sealant necessary for the application.

Use the following procedure to install the band

clamps to hold the cartridge to the compressor

housing:

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |