TM 5-3815-221-14&P

the wedge is in its final position. When seated properly

wedge will just protrude beyond the end of the socket

4. Cut a piece of rope and secure it to the end of the with

two clamps as shown in Figure 6.

PITCH BRACES

Install the pitch braces as follows:

1. Note that three holes have been provided in the d stick

for dipper pitch adjustment (Figure 1). Position back hoe

boom over rear of crawlers and extend dipper ha until

dipper teeth are in the vertical position.

2. Lower dipper to ground and remove hardware v

secures brace to dipper handle.

3. To shorten braces, move crawler backward slowly

holes in braces are aligned with holes in dipper hand

4. To lengthen braces, move crawler forward slowly.

5. When the holes are aligned, install the pin, washer

cotter pins.

REMOVING BACKHOE ATTACHMENT

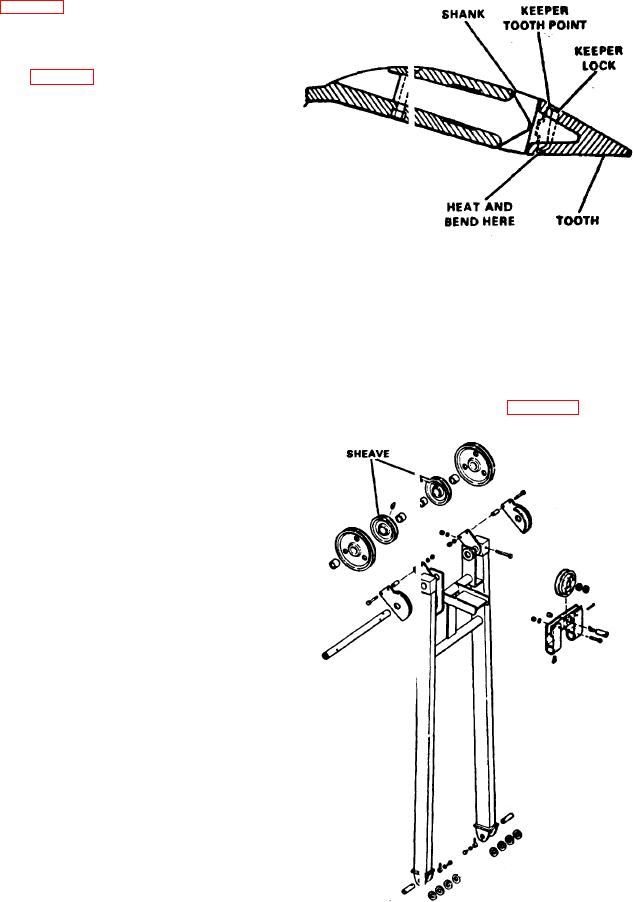

Figure 7. Dipper Tooth Replacement

To remove the backhoe attachment, proceed as folloows

1. Pull dipper in under boom and lower dipper to ground

4. Install the tooth point keeper and wedge in with lock

Provide blocking between dipper and dipperstick.

keeper. Heat section of lock keeper indicated to glowing

2. Remove cable from both drums. Roll cable into a coil

red, then bend tang as shown

secure with wire. Label the cable for future use.

3. Crib backhoe boom to support it for removal from the

GANTRY ASSEMBLY

revolving frame.

4. Drive a wedge between cribbing and boom to remove

If the gantry is disassembled for sheave or pin

weight of boom from boom foot pins.

replacement, install sheave (see Figure 8) so grease

5. Remove boom foot pins. Slowly back machine away

fitting is facing toward center line of gantry.

boom.

6. Slack off on boom hoist cable and lower auxiliary

gantry onto blocking on both ends.

7. Remove backstop assembly from auxiliary gantry and

machine.

8. Crib auxiliary gantry to support it for removal from the

revolving frame.

9. Unreeve boom hoist cable from gantry. Slowly take

boom hoist drum to unreeve cable.

10 Drive a wedge between cribbing and gantry to remove

weight of gantry from gantry foot pins.

11. Remove gantry foot pins. Slowly back machine from

gantry.

DIPPER TOOTH REPLACEMENT

Dipper teeth must be replaced when worn to one-third

original length. To replace the teeth, proceed as follow

Figure 7):

1. Drive the tooth lock keeper and tooth point keeper out

of the tooth shank

2 Remove the tooth from the shank.

3. Install a new tooth on shank.

Figure 8. Gantry (2100N522)

6