|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

GENERAL REPAIR METHODS (CONT)

CAUTION

Do not attempt to use parts of a 37-degree flare fitting and a flareless

f i t t i n g with each other. Fitting will leak.

W h e n c o n n e c t i n g N P T s , u s e care not to overtighten. If overtightened,

f e m a l e pipe thread will split.

Do not apply sealant to first thread of NPT fitting. If sealant enters

h y d r a u l i c system, it may cause components to fail.

Be careful when installing preformed packings. Sharp threads can nick

p a c k i n g , causing it to leak.

Do not overtighten a flareless connection. Overtightening can cause leakage

r e q u i r i n g replacement of entire tube assembly.

When connecting a hose to fitting, always use two wrenches. Use one

w r e n c h to turn swivel nut onto fitting and other wrench to keep hose or

t u b e from rotating. Failure to do so could result in damage to equipment.

The following describes the types of fittings used in the vehicles. Refer to this information when

performing hydraulic maintenance tasks.

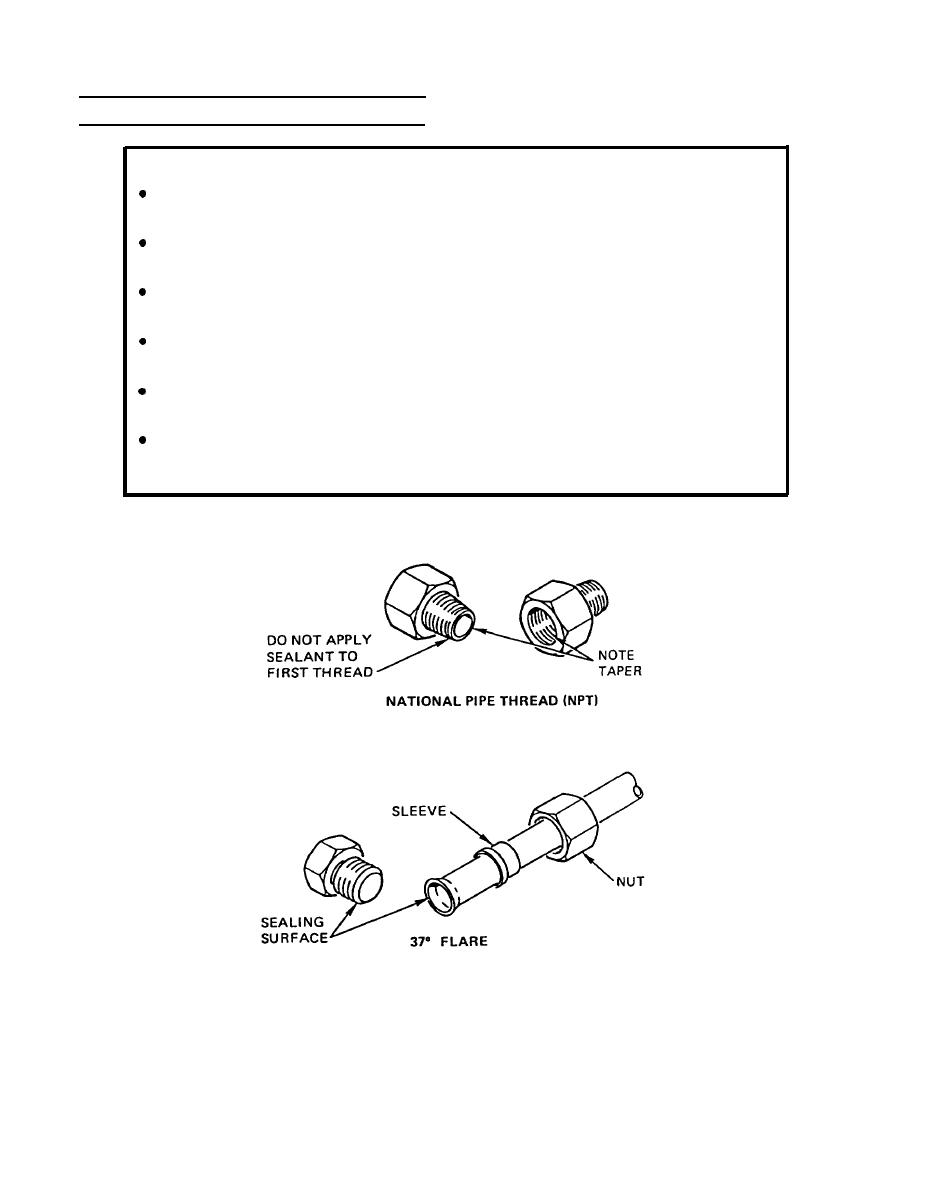

National Pipe Thread (NPT). This thread differs from others in that it is tapered. To obtain a

1.

proper seal with NPT, a sealant must be used. The sealant should be applied to male threads.

Use care not to overtighten.

2.

37-Degree Flare. The 37-degree flare connection has a male straight thread that mates with a

female straight thread. The sealing surface for this connection is the angled nose at the end of

the male fitting. The nose mates with a similar surface in the female 37-degree flare fitting.

These sealing surfaces must be free of nicks and scratches to seal properly.

2-40

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |