|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2420-224-34

Table 2-1. Troubleshooting

Malfunction

Test or Inspection

Corrective Action

ENGINE

Step 1.

Remove fuel injector nozzles. Check for blocked fuel injector spray holes by

performing fuel injector spray pattern test (page 13-65).

Repair fuel injector nozzle(s) (page 13-65).

Step 2. Perform compression test as follows:

a. Run engine until it reaches normal operating temperature of 140-185F

(60-85 C). Shut off engine.

b. Remove six fuel injector nozzles (page 3-41).

c. Crank engine several times to remove carbon flakes and dirt.

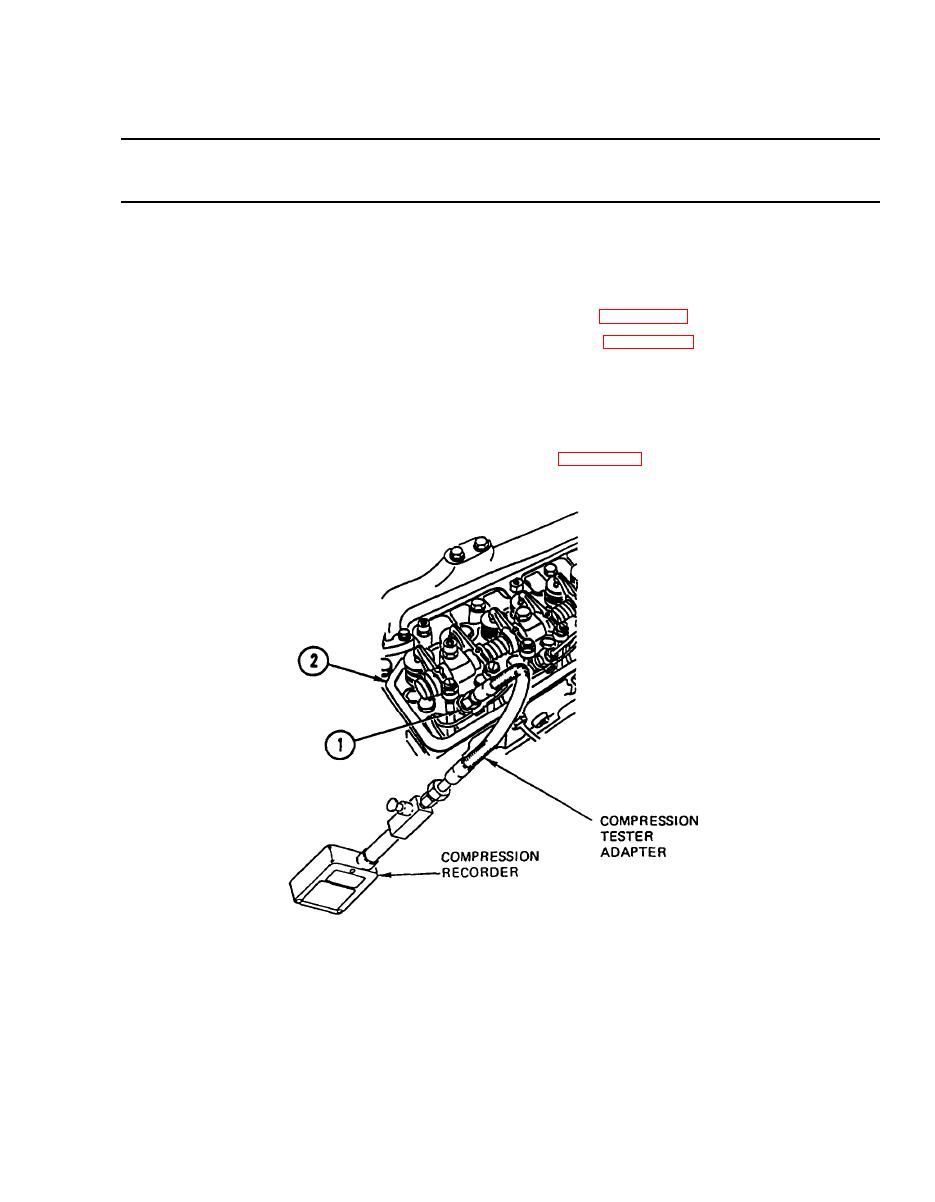

Clean fuel injector nozzle seat base (1) in cylinder head (2).

d.

Place compression tester adapter (P/N 352 589 00 21 00) into protective

e.

sleeve. Install nozzle holder nut. Tighten nozzle holder nut to 50 Ib-ft

(68 Nm).

f.

Connect compression recorder to compression tester adapter. Crank

engine several times until highest reading is obtained. Record highest

reading. Minimum acceptable compression reading is 284 psi (20 bar).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |