|

| |

TM 5-2420-222-34

5-1.

FUEL INJECTION NOZZLES TEST AND REPAIR (Con’t).

13. Inspect adjusting nut, lift adjusting screw, pressure adjusting screw, locknut, spring, and spring seat for cracks, bends,

breaks, or stripped threads. If damaged, replace fuel injection nozzle.

14. Inspect all other metal parts for cracks, breaks, abnormal bends, and damaged threads. Replace defective parts.

d.

REPAIR

WARNING

•

No open flames, welding, grinding, smoking, or use of heat producing devices

permitted nearby when using fuel. Fuel burns easily and fumes are explosive.

Keep battery disconnected. Failure to observe these precautions may cause

serious Injury or death to personnel.

•

Plastic gloves must be worn and kept clean and lubricated with clean diesel fuel

while working on internal parts of fuel injection nozzle. Ensure that work are is

exceptionally clean. Dirt and lint will cause damage, excessive wear leakage, or

clogs to fuel injection nozzles.

1.

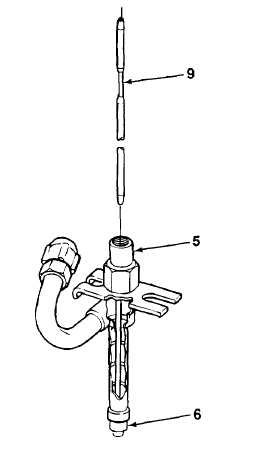

If fuel injection nozzle (5) has shown spotty chatter or signs of

sticking and low return leakage during test, place a small amount of

lapping compound on guide area of valve (9).

2.

Slide valve (9) into fuel injection nozzle (5). Using valve retractor,

grip top of valve and turn in fuel Injection nozzle 10-20 times. Raise

and lower valve every three turns.

3.

Remove valve (9) from fuel injection nozzle (5) and rinse thoroughly

with clean diesel fuel.

4.

If excess leakage was detected at nozzle tip (6) during test, place a

small amount of lapping compound on tip of valve (9) only.

5. Slide valve (9) into fuel injection nozzle (5). Using valve retractor,

grip top of valve and turn in fuel injection nozzle three to five times.

6.

Remove valve (9) from fuel injection nozzle (5) and rinse thoroughly

with clean diesel fuel.

5-6

|