|

| |

TM 5-2420-222-34

5-1.

FUEL INJECTION NOZZLES TEST AND REPAIR (Con’t).

c.

CLEANING AND INSPECTION

WARNING

•

No open flames, welding, grinding, smoking, or use of heat producing devices

permitted nearby when using fuel. Fuel burns easily and fumes are explosive.

Keep battery disconnected. Failure to observe these precautions may cause

serious Injury or death to personnel.

•

Plastic gloves must be worn and kept clean and lubricated with clean diesel fuel

while working on internal parts of fuel injection nozzle. Ensure that work area is

exceptionally clean. Dirt and lint will cause damage, excessive wear, leakage, or

clogs to fuel injection nozzles.

1.

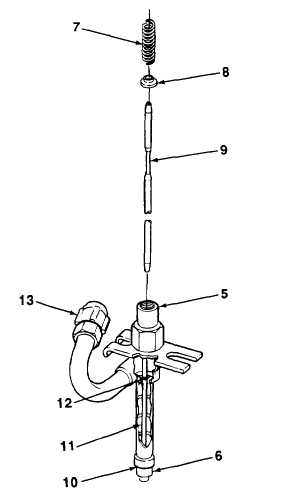

Using brass wire brush, clean carbon washer groove (10) in

fuel injection nozzle (5).

2.

Using machinist’s rule, clamp 0.008 in. cleaning wire in pin

vise, so that cleaning wire extends no more than 1/3 in.

(0.79 mm) out of pin vise.

3.

Using sharpening stone, flatten one side of cleaning wire to

aid in removing carbon deposits from fuel injection nozzle(s).

4.

Insert 0.008 in. cleaning wire in fuel injection nozzle holes

and rotate from side to side to remove carbon deposits from

fuel injection nozzle(s).

5.

Remove 0.008 in. cleaning wire from vise and repeat steps

2 through 4 using 0.01 in. cleaning wire.

6.

Using tip seat scraper, remove any carbon deposits from

valve seating area (12) of fuel injection nozzle (5).

7.

Using sac hole drill and valve retractor, remove any carbon

deposits from sac hole (11).

8.

Using brass wire brush, remove any carbon deposits from

seating area on tip of valve (9). If varnish is present, remove

with a lint-free wipe.

9.

Clean all other metal parts with clean diesel fuel.

10. Inspect fuel injection nozzle for cracks, breaks, and

abnormal bends.

11. Using inspection magnifier, inspect nozzle tip (6) for cracks,

breaks, abnormal bends, chipping, and erosion.

12. Inspect valve (9) for cracks, breaks, and abnormal bends. Using inspection magnifier, look for scratches which could

cause sticking.

TA701319

5-5

|