|

| |

TM 5-2420-222-34

5-1.

FUEL INJECTION NOZZLES TEST AND REPAIR (Con’t).

e.

ASSEMBLY

WARNING

No open flames, welding, grinding, smoking,

or use of heat producing devices permitted

nearby when using fuel. Fuel burns easily and

fumes

are

explosive.

Keep

battery

disconnected. Failure to observe these

precautions may cause serious Injury or death

to personnel.

Plastic gloves must be worn and kept clean

and lubricated with clean diesel fuel while

working on Internal parts of fuel Injection

nozzle.

En-

sure

that

work

area

Is

exceptionally clean. Dirt and lint will cause

damage, excessive wear, leakage, or clogs to

fuel injection nozzles.

CAUTION

Soak all fuel Injection nozzle internal parts In

clean diesel fuel before assembly. Fuel

injection nozzle Internal parts which have not

been thoroughly soaked in diesel fuel before

assembly will be damaged during test or

operation.

1.

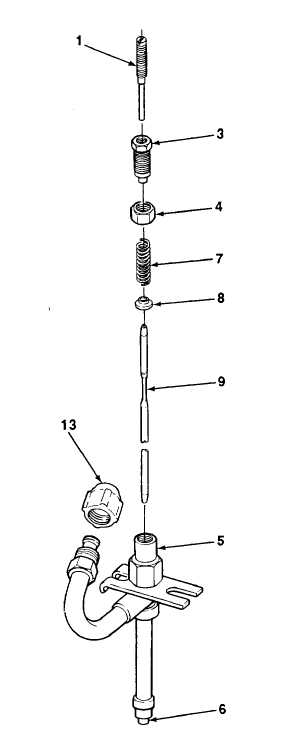

Soak valve (9), pressure adjusting screw (3), lift adjusting

screw (1), spring (7), and spring seat (8) in clean diesel

fuel.

2.

Install dust cap (13) on fuel injection nozzle (5).

3.

Slide valve (9) into fuel injection nozzle (5).

4.

Install lift adjusting screw (1) partway on pressure adjusting

screw (3).

5.

Install adjusting nut (4) on pressure adjusting screw (3) as

far as it will go.

6.

Install spring (7) and spring seat (8) on pressure adjusting

screw (3). Ensure that parts do not fall off.

7.

Install pressure adjusting screw (3) with assembled parts in

fuel injection nozzle (5) and valve (9). Tighten adjusting nut

(4) until snug, then loosen one full turn.

TA701321

5-7

|