|

| |

TM 5-2420-222-34

5-1.

FUEL INJECTION NOZZLES TEST AND REPAIR (Con’t).

b.

DISASSEMBLY

WARNING

•

No open flames, welding, grinding, smoking, or use of heat

producing devices permitted nearby when using fuel. Fuel burns

easily and fumes are explosive. Keep battery disconnected.

Failure to observe these precautions may cause serious Injury or

death to personnel.

•

Plastic gloves must be worn and kept clean and lubricated

with clean diesel fuel while working on Internal parts of fuel

Injection nozzle. En- sure that work area Is exceptionally

clean. Dirt and lint will cause damage, excessive wear,

leakage, or clogs to fuel Injection nozzles.

CAUTION

Disassemble, clean, Inspect, and assemble fuel Injection nozzles

one at a time to avoid mixing parts. Fuel Injection nozzle parts

are machined to very close tolerances. Mixing parts may cause

leakage, poor performance, or damage to parts.

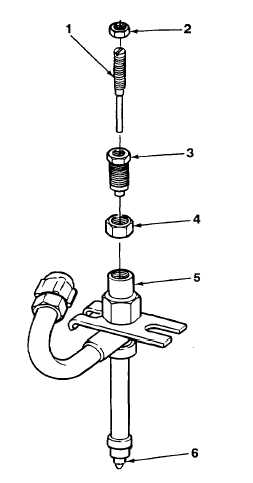

1.

Position fuel Injection nozzle (5) with assembled parts in nozzle

holding fixture and vise.

2.

Loosen adjusting nut (4) partway. Remove locknut (2) from

pressure adjusting screw (3) and lift adjusting screw (1).

3.

Remove pressure adjusting screw (3), lift adjusting screw (1), and

adjusting nut (4) from fuel injection nozzle (5).

4.

Remove fuel injection nozzle (5) with assembled parts from nozzle

holding fixture and vise. Do not tip fuel injection nozzle and spill

internal parts.

CAUTION

Do not bend valve when removing it from fuel injection nozzle. Bending may

damage parts.

5.

Tilt fuel injection nozzle (5) and allow spring (7), spring seat (8), and valve (9) to slide into hand. If valve does not

slide freely from nozzle, use valve retractor to remove valve.

6.

Remove lift adjusting screw (1) and adjusting nut (4) from pressure adjusting screw (3).

7.

Remove dust cap (13) from fuel injection nozzle (5).

TA701318

5-4

|