|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-241O-237-34

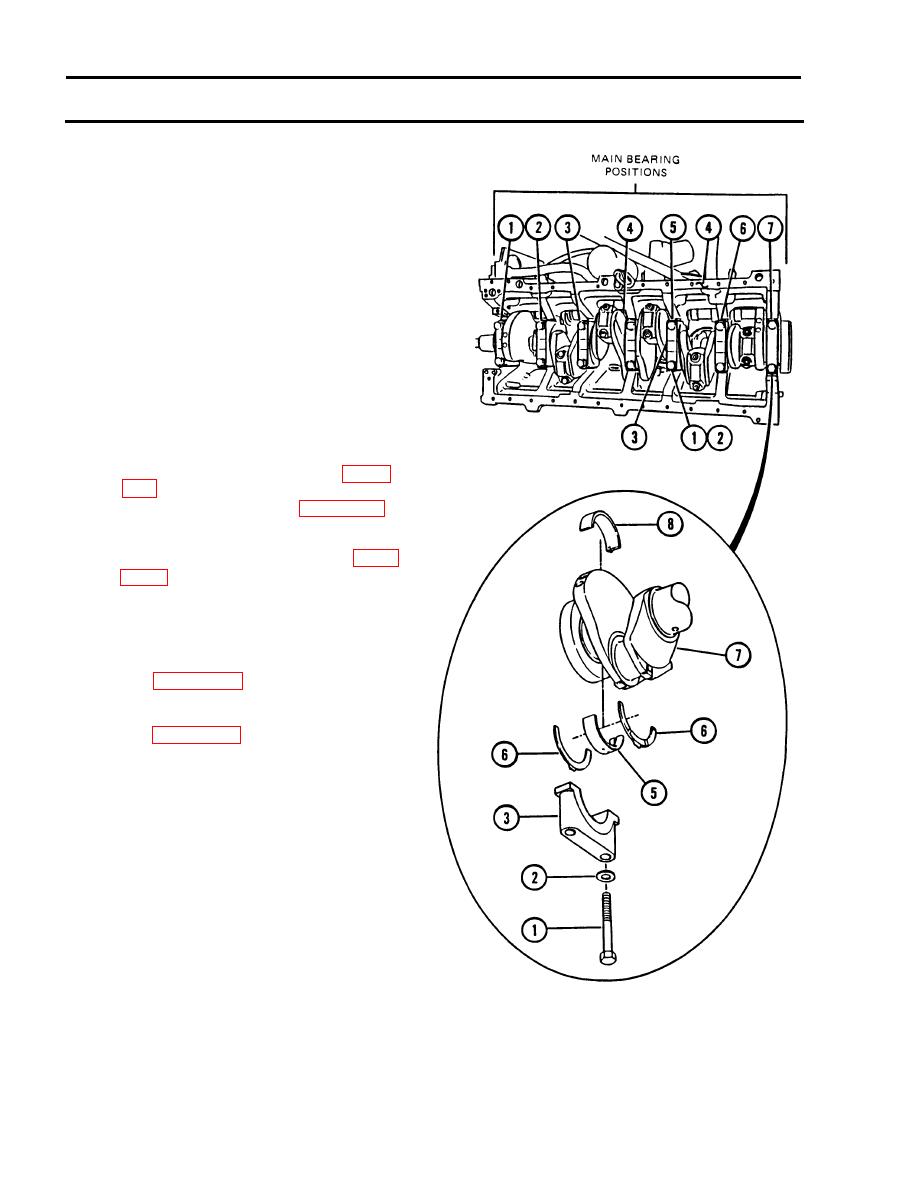

3-11. CRANKSHAFT BEARINGS - REPLACE (Cont'd)

(4) Inspect main bearing bores in the

block for cracks, chips,

distortion, thread damage, or

other damage. Replace a damaged

block.

(5) Inspect main bearing caps for

cracks, chipping or fretting

mating surfaces, and distortion

around the threaded bores.

Replace bearing cap if any of

these conditions exist.

(6) Install bearing caps (3), without

lower bearing halves, and

capscrews (1). Use a wrench to

tighten capscrews to a torque of

27 to 33 lb. ft., and take

measurements as shown in Table

are not as shown in Table 3-3,

replace the bearing cap. If

bearing cap replacement does not

alleviate the problem, see page

3-44 for repair of crankshaft

assembly. Remove capscrews and

bearing caps.

(7) Inspect crankshaft and measure

crankshaft main bearing journals.

See page 3-47 for crankshaft

inspection instructions.

(8) See page 3-32 for general

Inspection Instructions.

3-54

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |