|

|||

|

|

|||

|

Page Title:

Table 2-1. Direct Support and General Support Troubleshooting Table - continued |

|

||

| ||||||||||

|

|

TM5-241O-237-34

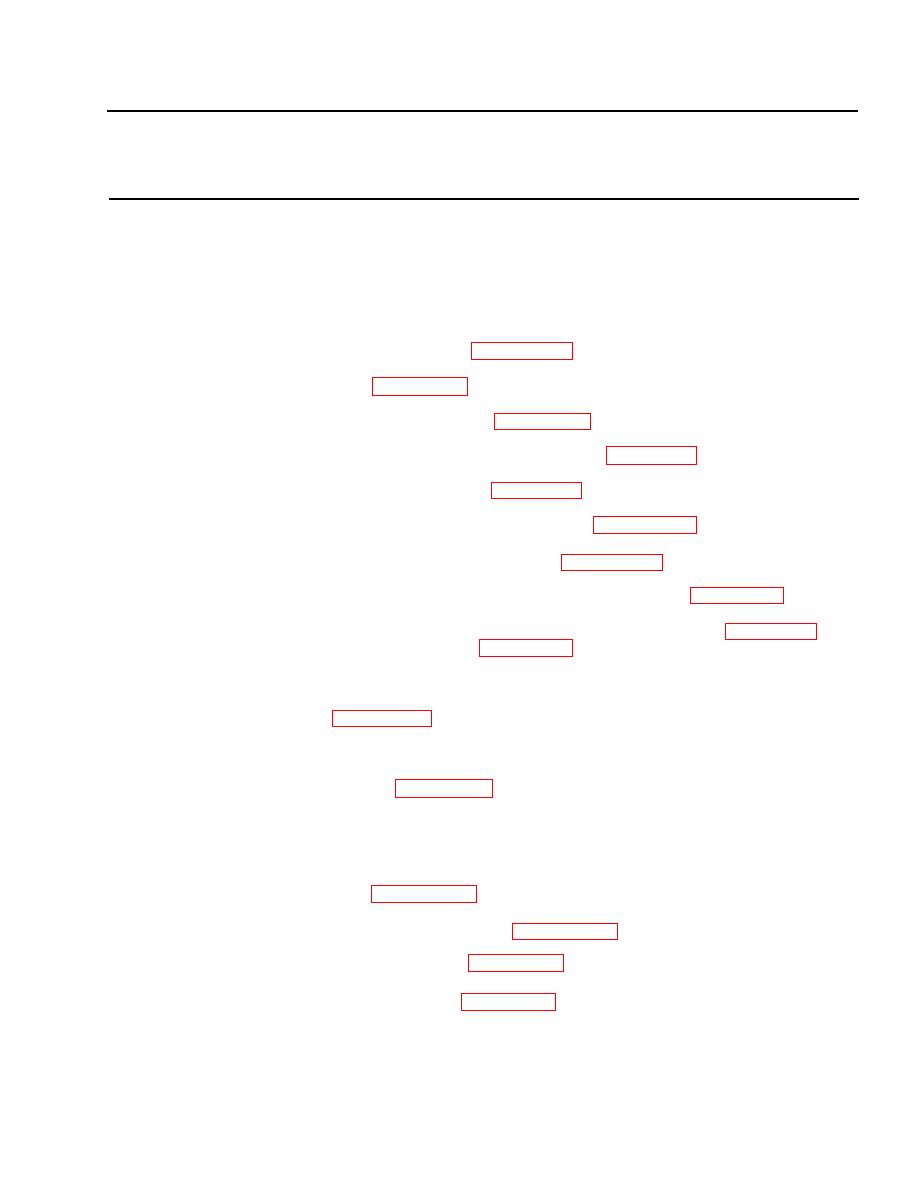

Direct Support and General Support Troubleshooting Table (Cont'd)

Table 2-1.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5.

LOW OIL PRESSURE

Step 1.

Check for fuel in engine lubrication system.

Find the place where fuel is entering. Repair is required.

Check for restriction at oil pump inlet. Clean inlet screen, or replace

Step 2.

inlet pipe or strainer assembly (page 3-111).

Step 3.

Inspect piston rings (page 3-77).

Replace piston rings, if necessary (page 3-77).

Step 4.

Check rocker arm-to-rocker arm shaft clearance (page 3-95).

Repair or replace valve mechanism (page 3-95).

Step 5.

Check camshaft-to-camshaft bearings clearance (page 3-104).

Replace camshaft and/or camshaft bearings (page 3-104).

Step 6.

Check crankshaft journal-to-crankshaft bearing clearance (page 3-51).

Replace crankshaft bearings (3-51) or connecting rod bearing (page 3-77)

and repair or replace crankshaft (page 3-43).

Step 7.

Check oil pump idler gear bearing clearance.

Replace bearing (page 3-111).

Inspect engine oil pump.

Step 8.

Repair or replace pump (page 3-111).

END OF TESTING!

6. ENGINE KNOCKS (MECHANICAL NOISE)

Step 1.

Inspect timing gears (page 3-108).

Replace timing gear(s), if necessary (page 3-108).

Step 2.

Inspect connecting rod bearings (page 3-85).

Replace bearings, if necessary (page 3-85).

2-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |